Why UV Laser Technology Requires a Professional UV Laser Marker Supplier

Learn why UV laser technology requires a skilled UV Laser Marker supplier and a reliable UV Laser Marker factory. Discover how expertise ensures precision and long-term performance.

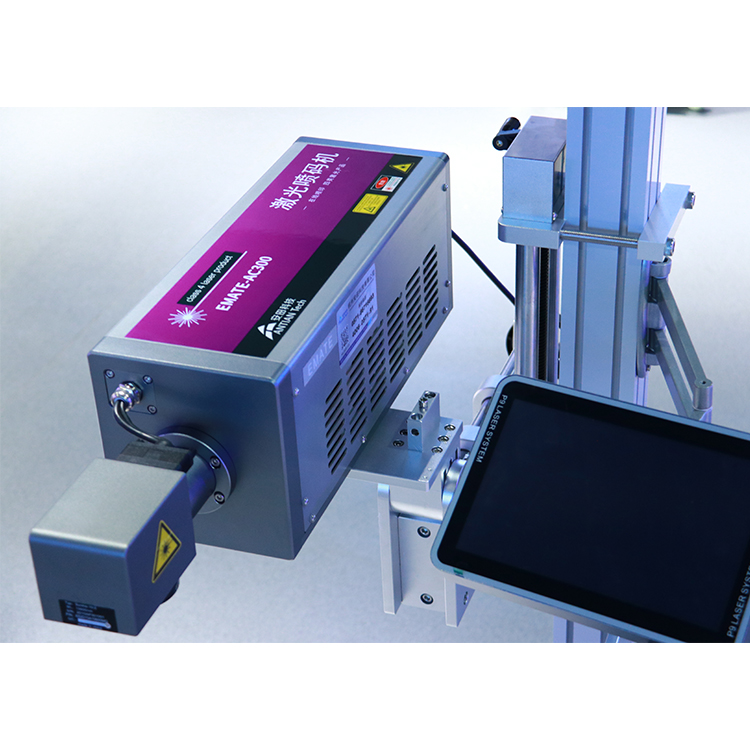

Ultraviolet (UV) laser marking has become one of the most precise and reliable marking methods in the industrial world. Whether used for electronics, medical devices, packaging, or micro-engraving applications, UV laser markers provide exceptional detail and extremely fine marking quality. However, because UV laser systems involve advanced optics, high-frequency lasers, and complex cooling structures, selecting a professional UV Laser Marker supplier is critical.

A high-quality UV laser system cannot be produced without the expertise, engineering, and manufacturing capabilities that come from a trusted UV Laser Marker factory. In this article, we’ll explore why UV laser technology needs professionals and what businesses should look for when choosing the right supplier or factory.

Understanding the Complexity of UV Laser Marking Technology

UV laser marking requires far more precision than CO₂ or fiber laser marking. UV lasers operate at a 355nm wavelength, which allows them to mark materials through a “cold marking” process. This means they vaporize surface layers without burning, melting, or damaging the underlying material.

Because of this precision, a professional UV Laser Marker supplier is essential for ensuring:

- High-quality UV light sources

- Precise optical path alignment

- Stable laser power output

- Controlled heat dissipation

- Long operating lifespan and reduced attenuation

A trusted supplier understands the unique engineering challenges behind UV systems and provides equipment that maintains stable performance in demanding industrial environments.

Why Expertise From a UV Laser Marker Supplier Matters

Expertise in UV Optics and Beam Quality

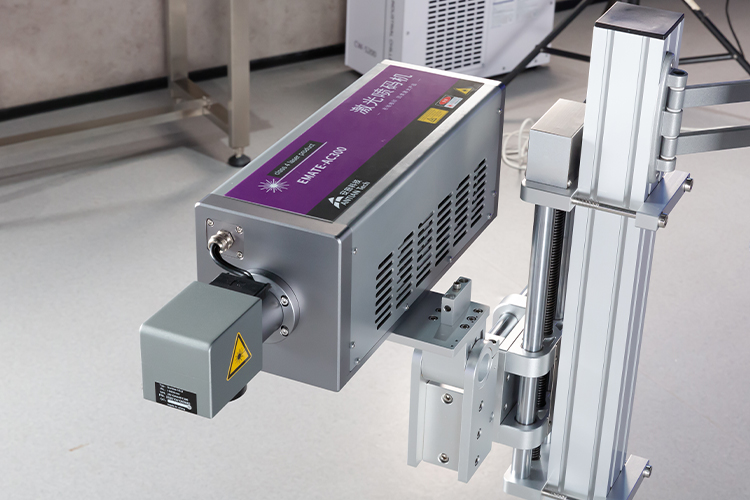

The quality of UV laser marking depends heavily on the optical components inside the machine. A reliable UV Laser Marker supplier uses high-grade mirrors, lenses, and galvanometer systems that can withstand ultraviolet wavelengths without degrading.

Poor-quality optics lead to problems such as:

- Irregular beam spots

- Inconsistent marking depth

- Fast optical wear and replacement costs

- Reduced precision in fine markings

Only a professional supplier with specialized UV experience can ensure consistent beam performance.

Why UV Laser Manufacturing Must Take Place in a Professional UV Laser Marker Factory

Producing a UV laser marker requires specialized manufacturing conditions. A professional UV Laser Marker factory operates with strict environmental controls, dust-free assembly areas, and advanced calibration equipment.

A professional factory ensures:

- Accurate alignment of optical paths

- Stable beam uniformity

- Reliable UV source integration

- Rigorous temperature and vibration testing

These processes directly influence how long the laser system will last and how consistently it will perform.

Choosing the Right UV Laser Marker Supplier or Factory

UV laser technology is sophisticated, delicate, and requires an expert approach at every stage from design to production to installation. That’s why choosing a professional UV Laser Marker supplier or partnering with a reliable UV Laser Marker factory is essential.

With precise optics, advanced manufacturing processes, industry-specific knowledge, and strong after-sales service, a professional supplier ensures that your UV laser marking equipment delivers accuracy, durability, and long-term performance.