Next Generation Inkjet Printing for Manufacturing and Design

Discover how next generation inkjet printing transforms manufacturing and design with advanced automation, UV printing technology, and versatile industrial applications that deliver efficiency, durability, and high-quality results.

Introduction

Printing has evolved dramatically over the last few decades. From simple office inkjet printers to sophisticated large-format UV printers, today’s printing technology goes far beyond documents and photos. Businesses in packaging, signage, décor, textiles, and industrial manufacturing now rely on fully automatic inkjet printers and large UV inkjet printers to achieve efficiency, versatility, and premium quality.

As industries embrace automation and sustainability, the demand for smart, high-speed, and versatile printing equipment is rising. Whether it’s mass production of product labels, printing intricate designs on rigid surfaces, or delivering durable large-format displays, industrial inkjet printers have become a cornerstone of modern production lines.

In this article, we’ll explore what fully automatic inkjet printers and large UV inkjet printers are, their advantages, applications, key differences, and how businesses can choose the right system for their needs.

What Is a Fully Automatic Inkjet Printer?

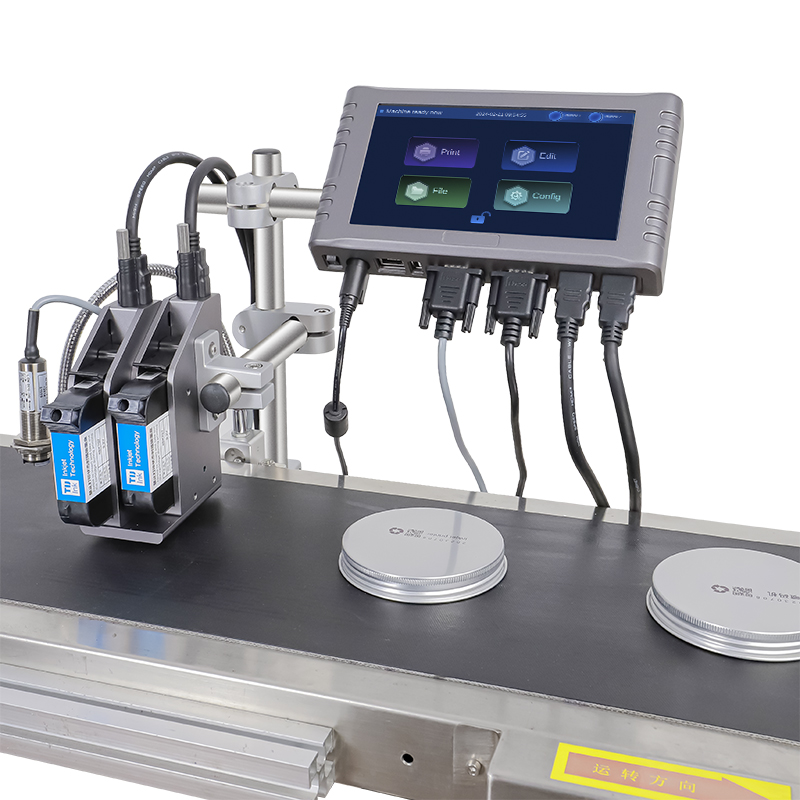

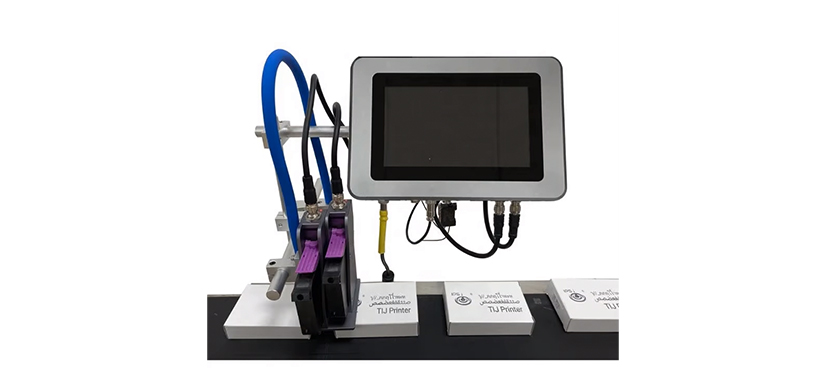

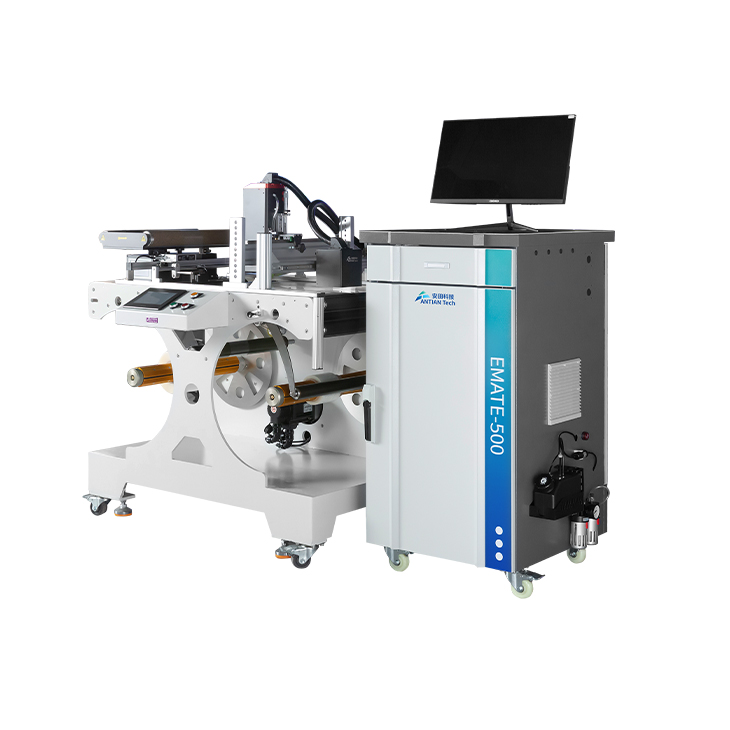

A fully automatic inkjet printer is an advanced industrial printing machine designed to minimize human intervention. Unlike traditional printers, which often require manual feeding, alignment, or handling, fully automatic inkjet printers handle these processes autonomously.

How They Work:

l Automatic Feeding: Materials such as paper, plastic sheets, textiles, or labels are automatically loaded into the machine.

l Precision Alignment: Built-in sensors ensure accurate positioning for consistent prints.

l High-Speed Inkjet Technology: Uses fine nozzles to spray ink droplets directly onto the substrate.

l Integrated Drying or Curing Systems: Ensures quick setting of inks, reducing smudging and downtime.

l Automated Output Handling: Finished products are stacked, rolled, or cut without manual interference.

This level of automation not only boosts productivity but also enhances consistency in large-scale industrial printing environments.

Advantages of Fully Automatic Inkjet Printers

1. High Efficiency and Productivity

Automation eliminates bottlenecks in the production line. Businesses can achieve continuous, round-the-clock printing without manual monitoring, significantly increasing throughput.

2. Consistent Print Quality

With sensors, automated calibration, and uniform ink distribution, fully automatic inkjet printers ensure every piece meets the same high-quality standard.

3. Reduced Manual Labor

Automation reduces dependency on skilled operators. This helps businesses lower labor costs while minimizing human error.

4. Cost-Effectiveness in Mass Production

Though the initial investment may be high, cost savings in labor, reduced waste, and higher productivity lead to strong ROI over time.

5. Integration with Smart Manufacturing

Many modern fully automatic printers integrate with ERP and MES systems, supporting Industry 4.0 initiatives where data and production are interconnected.

Applications of Fully Automatic Inkjet Printers

l Packaging Industry: Printing logos, barcodes, and graphics on cartons, labels, and pouches.

l Textile Industry: Automated printing on fabrics for apparel, upholstery, and accessories.

l Electronics: High-precision coding and marking on electronic components.

l Pharmaceuticals: Printing batch numbers, expiration dates, and traceability codes.

l Advertising & Labels: Automated label printing for FMCG and e-commerce sectors.

What Is a Large UV Inkjet Printer?

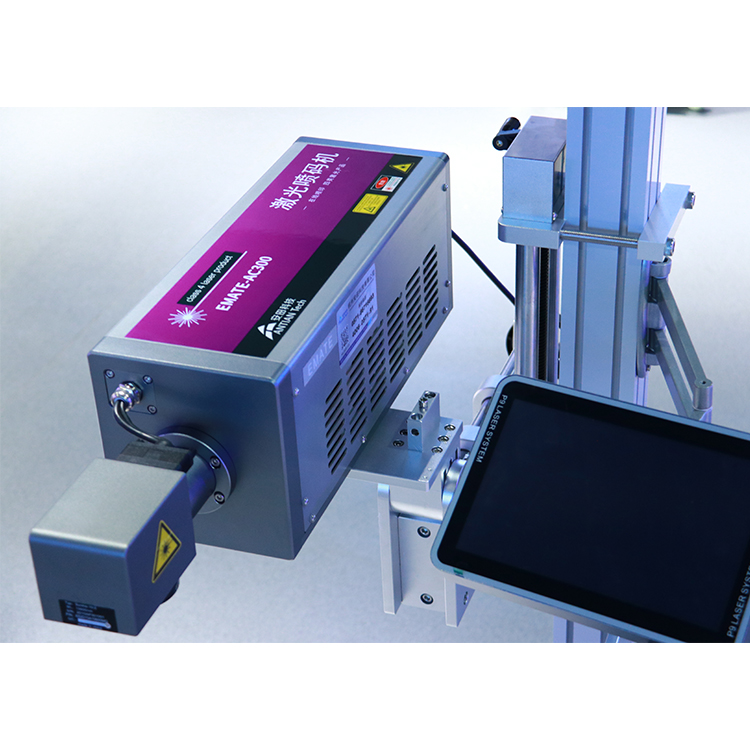

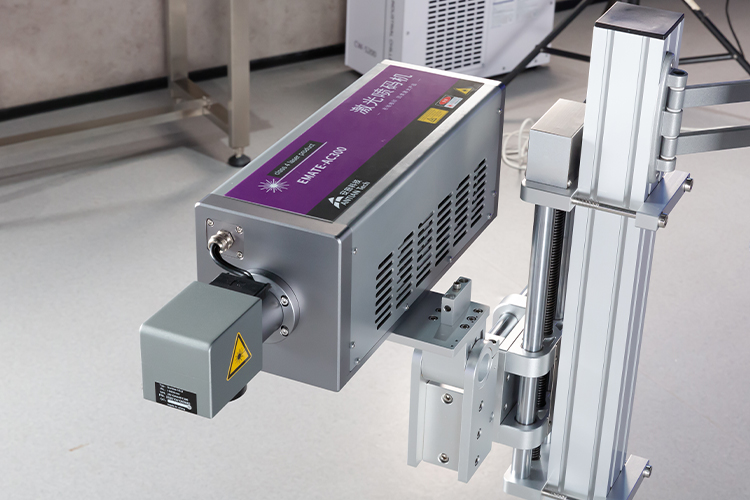

A large UV inkjet printer uses ultraviolet (UV) light to cure specially formulated inks as they are printed onto a surface. Unlike traditional printers that rely on absorption and drying, UV printers instantly cure ink, allowing them to print on a wide variety of rigid and flexible substrates.

How UV Printing Works:

l Ink Deposition: UV inks are jetted directly onto the substrate.

l Instant Curing: UV LED lamps cure the ink instantly, solidifying it onto the surface.

l Durable Finish: The result is a vibrant, scratch-resistant, and weatherproof print.

Compatible Materials:

l Glass, acrylic, and ceramics

l Metals (aluminum, stainless steel, coated surfaces)

l Plastics (PVC, ABS, PET, polycarbonate)

l Wood and MDF boards

l Fabrics and leather

l Paper and cardboard

This versatility makes UV inkjet printers particularly valuable in industries requiring customized, durable, and large-scale graphics.

Benefits of Large UV Inkjet Printers

1. Versatility Across Materials

Unlike conventional printers, UV inkjet printers can print directly on rigid and flexible substrates without the need for primers in most cases.

2. Durability of Prints

UV-cured inks are resistant to scratching, water, chemicals, and UV exposure, making them ideal for outdoor signage and long-term use.

3. Eco-Friendly Printing

Since UV curing produces minimal volatile organic compounds (VOCs), UV printing is considered safer and more environmentally friendly compared to solvent-based printing.

4. High-Quality, Vibrant Colors

The curing process locks pigments on the surface, resulting in vivid colors and sharp details. Advanced models can even produce 3D embossed textures.

5. Large Format Capability

Large UV inkjet printers are designed for banners, billboards, and industrial-scale production, making them indispensable in advertising and décor industries.

Key Features to Consider When Choosing an Industrial Inkjet Printer

l Print Resolution and Speed – Match the balance between quality and output volume.

l Supported Substrates – Ensure compatibility with your production materials.

l Ink Type & Curing Method – Water-based, solvent, UV-curable inks depending on requirements.

l Automation Features – Feeding systems, sensors, and integration with factory lines.

l Maintenance & Operating Costs – Evaluate ink consumption, spare parts, and service.

l Scalability – Ensure the system can grow with future demand.

Latest Trends in Inkjet Printing Technology

l AI-Powered Monitoring: Detecting print errors in real-time and adjusting automatically.

l Eco-Friendly UV Inks: Development of inks with lower environmental impact.

l Hybrid Printers: Combining UV inkjet with textile or packaging capabilities.

l Industry 4.0 Integration: Cloud-connected printers that integrate with smart manufacturing.

l 3D Printing-Like Effects: Raised textures and tactile finishes from advanced UV printers.

Choosing the Right Printer for Your Business

The decision between a fully automatic inkjet printer and a large UV inkjet printer depends on your industry, products, and long-term goals.

l For Packaging & Labels: A fully automatic inkjet printer ensures high-speed and cost-effective production.

l For Advertising & Décor: A large UV inkjet printer delivers durable, large-format prints.

l For SMEs: Start with the technology that matches your core products and expand later.

l For Large Manufacturers: Consider hybrid or dual systems for maximum flexibility.

ROI Considerations:

l Factor in labor savings, production efficiency, reduced waste, and new business opportunities enabled by advanced printers.

l A well-chosen printer is not just a machine—it’s an investment that pays for itself through higher productivity and revenue streams.

Conclusion

Fully automatic inkjet printers and large UV inkjet printers represent two powerful directions in industrial printing technology. While the former focuses on speed, automation, and mass production efficiency, the latter offers unmatched versatility, durability, and high-impact visual results.

Businesses in packaging, textiles, signage, décor, and beyond can gain significant competitive advantages by adopting these technologies. Whether your priority is automation, efficiency, or material versatility, investing in the right industrial inkjet printer ensures long-term growth, cost savings, and innovation in production.

In the age of smart manufacturing and sustainable practices, these printers are not just tools—they are strategic assets shaping the future of industrial printing.