How UV Inkjet Printing is Transforming Packaging and Industrial Design

Discover how UV inkjet printing is revolutionizing packaging and industrial design. Learn the advantages of UV inkjet printers, material compatibility, creative applications, and sustainable production solutions for modern industries.

UV inkjet printing has emerged as one of the most innovative technologies revolutionizing both packaging and industrial design. With the capability to produce high-resolution, durable, and customizable prints, UV inkjet printers are rapidly becoming a standard solution across multiple industries. This article explores how UV inkjet printing works, its advantages, applications, and future potential, providing a comprehensive view for designers, manufacturers, and packaging professionals.

Understanding How UV Inkjet Printing Works and Its Impact on Design

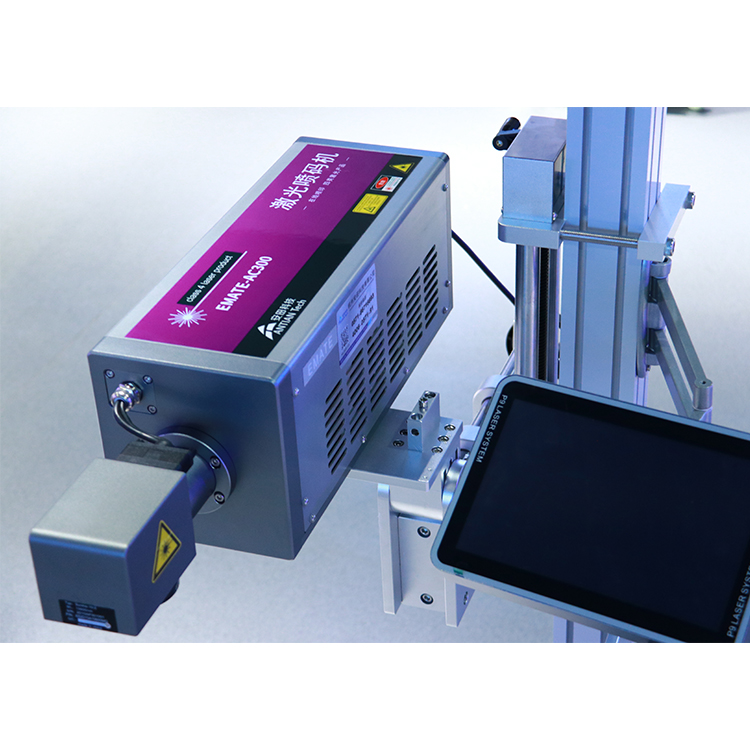

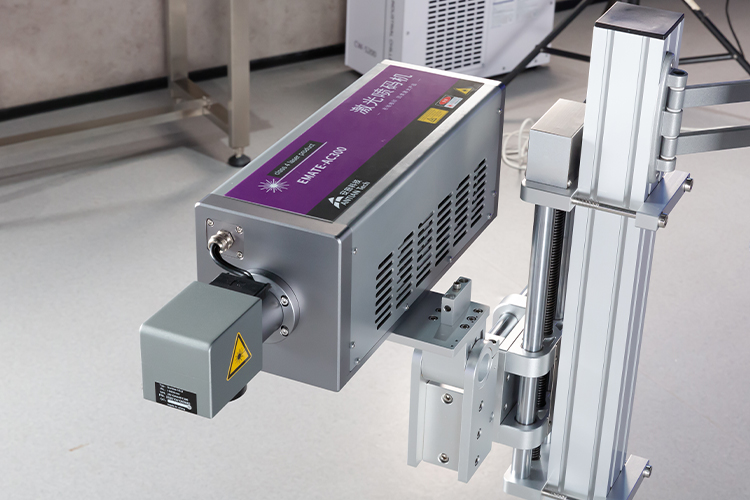

UV inkjet printing uses ultraviolet (UV) light to instantly cure liquid ink as it is printed onto a surface. Unlike traditional printing methods that rely on heat or chemical drying, UV inkjet printing allows ink to solidify immediately, resulting in sharper images, vibrant colors, and durable finishes.

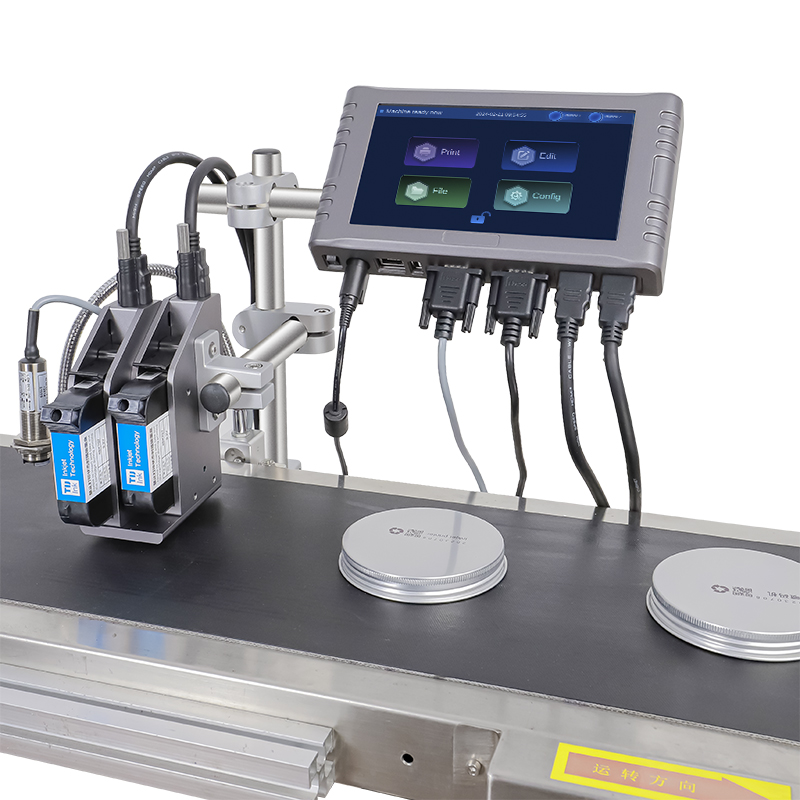

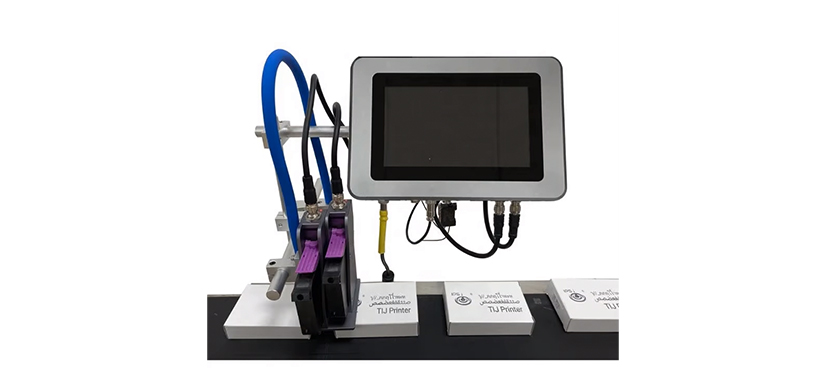

The process begins with the UV inkjet printer ejecting ink droplets onto a substrate. The UV light source then instantly hardens the ink, making it resistant to smudging or fading. This ability to print directly on a wide range of surfaces, including plastics, metals, glass, and cardboard, allows designers to experiment with textures, patterns, and finishes that were previously impossible.

From a design perspective, UV inkjet printing empowers creativity. Designers no longer have to compromise between aesthetics and functionality. Labels, packaging, and industrial components can now feature intricate graphics, embossed effects, and even metallic or textured finishes without slowing down production.

Key Advantages of Using a UV Inkjet Printer in Modern Packaging

There are several advantages that make UV inkjet printing a preferred choice in modern packaging:

- High-Resolution Output – UV inkjet printers deliver sharp and precise images, enhancing brand presentation and consumer appeal.

- Material Versatility – Unlike traditional methods, UV inkjet printing works on diverse substrates, allowing packaging across different products without multiple machines.

- Faster Production – Immediate curing reduces downtime, enabling high-speed production runs with consistent quality.

- Reduced Waste – On-demand printing reduces material and ink wastage, making the process cost-efficient and environmentally friendly.

The combination of speed, quality, and sustainability gives companies the flexibility to respond to market trends, customize packaging for different campaigns, and maintain consistent branding across product lines.

Comparing UV Inkjet Printing with Traditional Printing Methods

While offset, flexography, and screen printing have long been industry standards, UV inkjet printing introduces advantages that challenge traditional methods.

|

Feature |

Traditional Printing |

UV Inkjet Printing |

|

Drying Method |

Requires heat or time to dry |

Instant curing with UV light |

|

Substrate Compatibility |

Limited (paper, cardboard) |

Wide (plastics, metals, glass, films) |

|

Resolution |

Medium |

High, with fine details possible |

|

Customization |

Slower, requires setup |

Fast, ideal for variable data printing |

|

Environmental Impact |

More solvent use |

Minimal solvent, less waste |

From this table, it is clear that UV inkjet printing is not only faster and more flexible but also more environmentally sustainable, which is increasingly important for global brands.

Creative Applications of UV Inkjet Printing in Industrial Products

In industrial design, UV inkjet printing allows manufacturers to add value and differentiation to products. Applications include:

- Custom Branding: Logos, QR codes, and product information can be applied directly onto components with high precision.

- Decorative Finishes: Textures, metallic effects, and even tactile designs can be integrated seamlessly.

- Functional Markings: Barcodes, serial numbers, and traceability labels can be printed on non-traditional surfaces, supporting quality control.

Industrial designers leverage UV inkjet printers to create products that are not only functional but visually engaging. By integrating printing into the production workflow, companies reduce costs while offering unique designs that stand out in the market.

Exploring Material Compatibility for UV Inkjet Printing in Packaging

One of the most transformative aspects of UV inkjet printing is its material compatibility. Unlike traditional printing techniques that often require pre-treatment of surfaces, UV inkjet printers can print directly on:

- Plastics: High durability and color stability for bottles, containers, and flexible packaging.

- Metals: Resistant to abrasion and suitable for industrial components, electronics, and premium packaging.

- Glass: Ideal for cosmetic and beverage packaging, where clarity and elegance are important.

- Cardboard and Paper: High-resolution images and variable printing make it perfect for custom cartons.

This versatility allows companies to use a single printing solution for multiple products, reducing the need for separate equipment and streamlining production.

How UV Inkjet Printing Supports Sustainable Packaging Solutions

Sustainability is a critical concern in packaging today. UV inkjet printing contributes to greener production in several ways:

- Minimal Ink Waste – Precision printing applies only the necessary amount of ink, reducing excess.

- No Solvent Emissions – UV inks are often solvent-free, lowering environmental impact.

- On-Demand Printing – Small batch production is feasible without overproduction or surplus stock.

By adopting UV inkjet printing, brands can align with environmental goals and respond to consumer demand for eco-conscious products without sacrificing quality or speed.

Overcoming Common Challenges in UV Inkjet Printing

While UV inkjet printing offers numerous advantages, it does come with challenges:

- Initial Cost – UV inkjet printers can be more expensive than conventional equipment.

- Surface Adhesion – Some non-porous or coated surfaces may require pre-treatment for optimal adhesion.

- Maintenance – Regular cleaning of print heads and careful handling of UV ink are essential for consistent results.

Manufacturers can overcome these challenges by selecting the right printer model for their application, investing in staff training, and integrating preventive maintenance into production schedules.

The Future Role of UV Inkjet Printing in Packaging and Industrial Design

Looking forward, UV inkjet printing is expected to play a central role in packaging innovation and industrial product customization. Emerging trends include:

- Smart Packaging – Integration with QR codes, NFC, and augmented reality for interactive consumer experiences.

- Variable Data Printing – Personalized packaging and limited edition runs become more feasible.

- Automation Integration – Printers linked to production lines can optimize throughput while maintaining high quality.

The combination of creative potential, technical flexibility, and environmental benefits positions UV inkjet printing as a key driver of innovation in the coming years.

FAQ

Q1: What is the difference between UV inkjet printing and regular inkjet printing?

A: UV inkjet printing uses ultraviolet light to instantly cure the ink, resulting in higher durability, sharper images, and compatibility with a wider range of materials compared to traditional inkjet printing.

Q2: Can UV inkjet printing be used on metal and glass surfaces?

A: Yes, one of the main advantages of UV inkjet printing is its ability to print directly on non-porous materials such as metals, glass, and plastics without compromising quality.

Q3: Is UV inkjet printing environmentally friendly?

A: UV inkjet printing reduces waste, often uses solvent-free inks, and supports on-demand production, making it a more sustainable choice than many traditional printing methods.

Q4: What industries benefit most from UV inkjet printing?

A: Industries such as food and beverage, pharmaceuticals, consumer electronics, cosmetics, and industrial manufacturing benefit significantly due to precision, speed, and material versatility.