Key Technologies Used by Leading Fiber Laser Etching Machine Factories

Discover the advanced technologies used by top Fiber Laser Etching Machine factories and learn how a reliable supplier ensures precision, stability, and long-term performance.

As the global need for precision engraving and high-speed metal processing increases, more and more suppliers are choosing modern Fiber Laser Etching Machine systems. But at the core of every good system is an efficient Fiber Laser Etching Machine factory with a commitment to innovation and modern production methods. A perspective on core technologies employed at superior factories and factors considered at an experienced Fiber Laser Etching Machine seller can be most instructive.

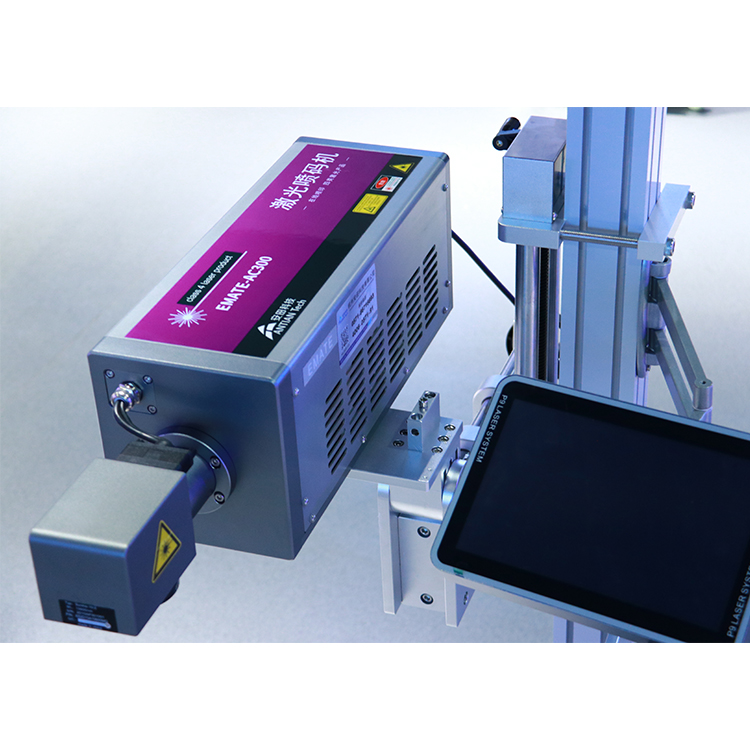

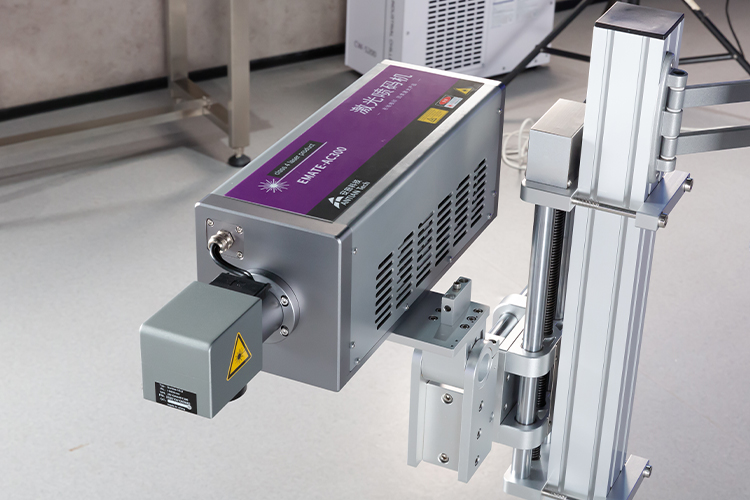

High-Performance Fiber Laser Sources Used in Leading Factories

At the heart of every fiber laser etching system is the laser source itself. A reputable Fiber Laser Etching Machine factory typically uses premium laser modules from well-known brands or produces them in-house under strict quality control.

Key Advantages of Advanced Laser Sources:

- Higher beam stability

- Longer operating lifespan

- Superior etching consistency

- Lower maintenance requirements

A professional Fiber Laser Etching Machine supplier will always highlight the brand, power options, and reliability of the laser source, as these directly influence engraving depth, speed, and precision.

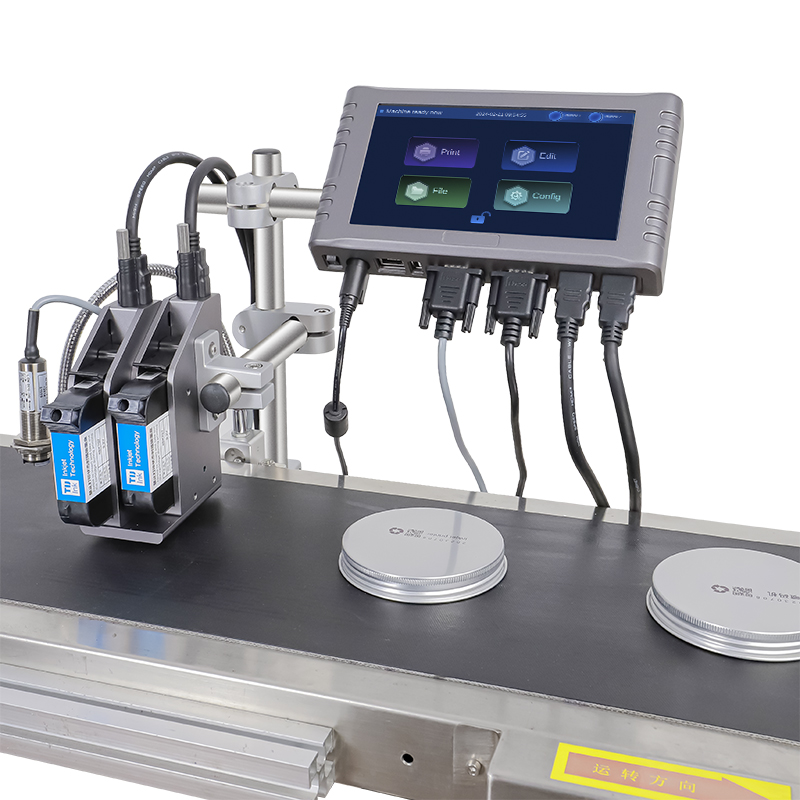

Intelligent Motion Control Systems for Precision Etching

Precision is critical in industries such as electronics, tools, automotive, aerospace, and medical devices. To achieve repeatable accuracy, top factories integrate advanced motion control technologies into their machines.

Technologies Commonly Used:

- High-speed galvanometer scanners

- Imported linear guides

- High-accuracy servo motors

- Closed-loop positioning systems

By combining quality hardware with sophisticated motion algorithms, a trustworthy Fiber Laser Etching Machine supplier ensures that the final product delivers fine lines, clean edges, and flawless marking even at high speeds.

Industrial-Grade Optical Components for Long-Term Stability

Optical quality often separates average machines from premium systems. Leading factories use industrial-grade optics designed to handle long-term laser exposure without distortion.

Key Optical Technologies Include:

- Anti-reflection coated lenses

- Durable F-theta scanning lenses

- Precision collimators and beam expanders

These components minimize energy loss and ensure consistent laser focus, which is essential for deep etching, high-contrast marking, and high-volume production environments.

A reputable Fiber Laser Etching Machine factory tests each optical module for temperature resistance, alignment accuracy, and beam uniformity before assembly.

Advanced Cooling Systems for Reliable Machine Operation

Heat management plays a major role in extending machine life. Leading factories integrate efficient cooling technologies to keep laser modules, optics, and control boards within optimal temperature ranges.

Cooling Techniques Used by Quality Factories:

- Intelligent air-cooling systems

- Temperature-controlled heat dissipation modules

- Smart airflow design for internal components

A responsible Fiber Laser Etching Machine supplier ensures that the machine can run continuously in factory environments without overheating or performance drops.

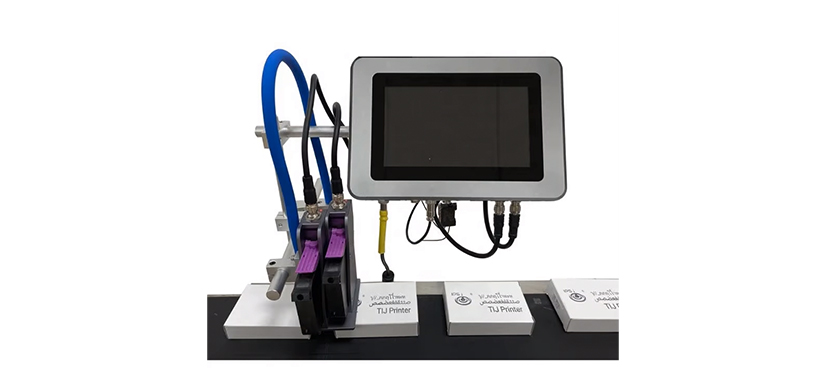

Smart Software Platforms for Flexible Etching Control

Modern fiber laser etching machines rely heavily on software for pattern generation, machine control, and automation. Top factories develop or customize software that is user-friendly, versatile, and compatible with major design formats.

Software Features Offered by Leading Factories:

- High-speed marking file processing

- Support for barcodes, QR codes, serial numbers, and graphics

- Automation integration (MES/ERP compatibility)

- Real-time preview and simulation

- Intelligent parameter recommendations

A good Fiber Laser Etching Machine supplier provides software training, updates, and support, ensuring customers can maximize machine capability with minimal learning time.

Rigorous Quality Control Processes in Modern Factories

Beyond individual components, production quality is what defines the reliability of a fiber laser etching machine. The best factories follow strict quality control systems, including:

- 100% component inspection

- Long-duration aging tests

- Beam quality testing

- Electrical safety certification

- Full performance verification before shipment

When choosing a Fiber Laser Etching Machine supplier, buyers should ask about the factory’s inspection process, certifications, and test reports to ensure consistent manufacturing standards.

Conclusion: Technology Defines the Strength of a Fiber Laser Etching Machine Factory

A good fiber laser etching machine needs more than just pure power. It needs advanced laser sources, high-precision motion control, advanced optic designs, efficient cooling systems, intelligent software, and strict factory-quality control. Having an efficient Fiber Laser Etching Machine supplier or acquiring from an advanced technologically based factory will aid businesses in getting maximum productivity and performance.