A Complete Guide to QR Code Automatic Inkjet Printers and Barcode Printing Solutions

Explore what these innovative printers are, how they work, their benefits, key features, industries that use them, buying considerations, and the future of QR code and barcode printing technologies.

In today's fast-paced industrial and commercial environments, automation and traceability are no longer optional—they're essential. The integration of QR code automatic inkjet printers and QR code barcode inkjet printers into production lines, logistics, and packaging systems has revolutionized how companies manage product identification, tracking, and compliance.

In this in-depth guide, we explore what these innovative printers are, how they work, their benefits, key features, industries that use them, buying considerations, and the future of QR code and barcode printing technologies.

What Is a QR Code Automatic Inkjet Printer?

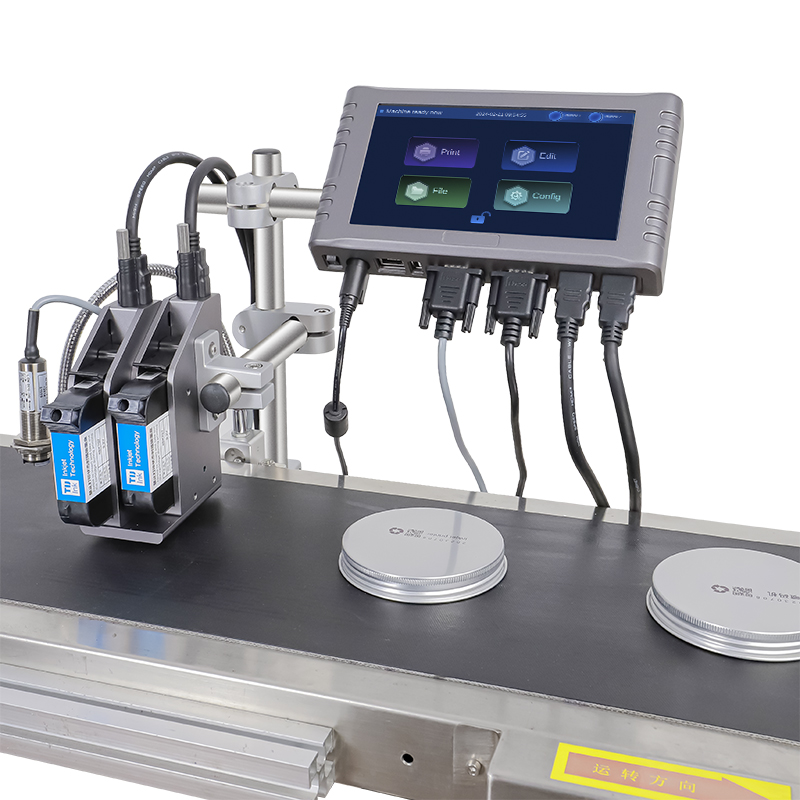

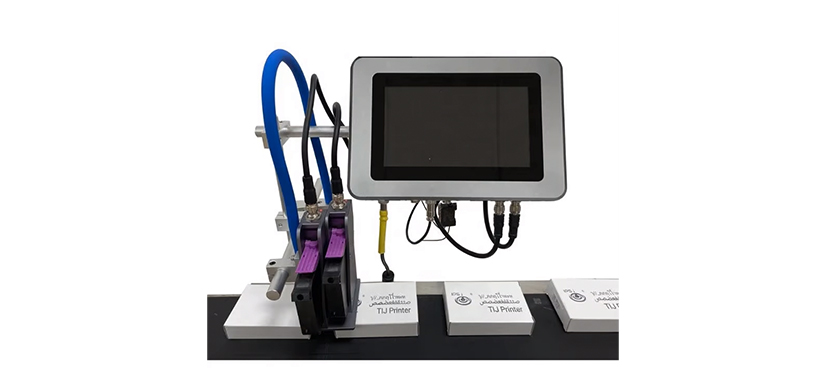

A QR code automatic inkjet printer is a specialized industrial printing device designed to automatically apply QR codes to a wide variety of products and packaging surfaces. Unlike manual labeling or static printing methods, these printers can dynamically print unique QR codes in real-time directly onto items as they move through a production line.

These printers use advanced inkjet technology to deposit precise droplets of ink onto surfaces, enabling high-resolution prints that are both machine-readable and visually clear. They are capable of operating at high speeds to match modern automated production environments, ensuring that every item is correctly marked without slowing down the workflow.

Key Components:

- Print Head: The core of the printer that controls the release of ink droplets to form QR code patterns. High-resolution print heads ensure that even dense codes are readable.

- Controller: A computer-like interface that manages printing instructions, stores QR code data, and interfaces with factory automation systems.

- Ink Supply System: Delivers consistent ink flow from cartridges or reservoirs to the print head. The system is optimized for different inks depending on substrate type.

- Sensors and Triggers: Detects the presence of a product and initiates the print sequence at the exact right moment.

These components work in harmony to ensure fast, accurate, and consistent printing, which is especially crucial for applications where product traceability and authentication are essential.

What Is a QR Code Barcode Inkjet Printer?

A QR code barcode inkjet printer is a more versatile version of the QR code inkjet printer. It is designed to print both 2D QR codes and traditional 1D barcodes (like UPC, EAN, or Code 128). This makes it ideal for industries that require multiple code formats on a single product for internal tracking, regulatory compliance, or customer-facing information.

The ability to print multiple types of codes from a single printer increases operational flexibility and reduces the need for separate labeling systems. These printers can adapt on-the-fly to different print jobs by switching between code formats and dynamically generating code data.

Differences from Standard Inkjet Printers:

- Code Versatility: Supports both QR codes and barcodes in various symbologies, enabling compliance with industry standards.

- Enhanced Resolution: Designed to handle the fine details required for high-density codes.

- Real-Time Data Printing: Connects to databases or ERP systems to generate variable codes in real-time.

- Serialization Support: Each printed code can be unique, which is crucial for traceability and anti-counterfeiting.

This type of printer is often used in sectors like pharmaceuticals, logistics, and electronics manufacturing, where accurate identification and data capture are mission-critical.

How These Printers Work

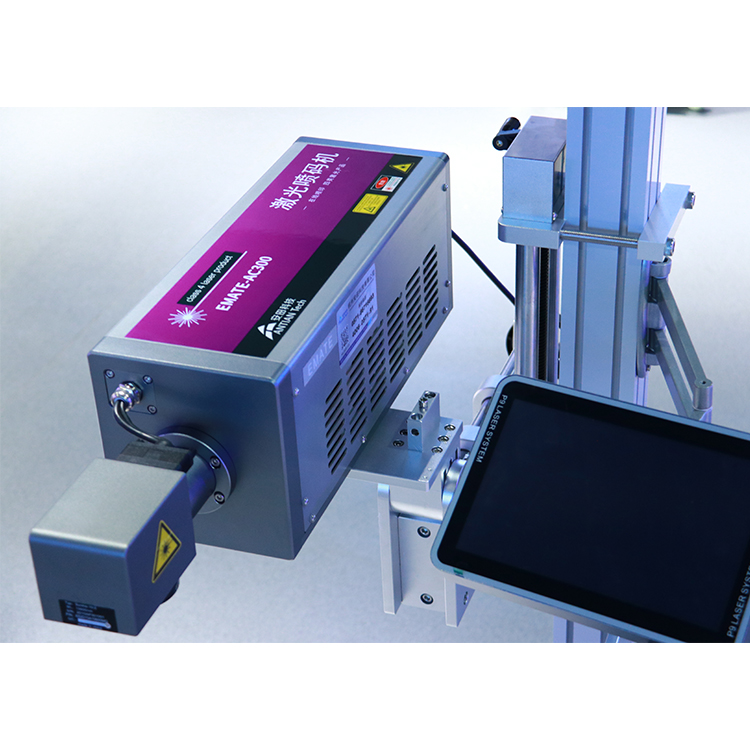

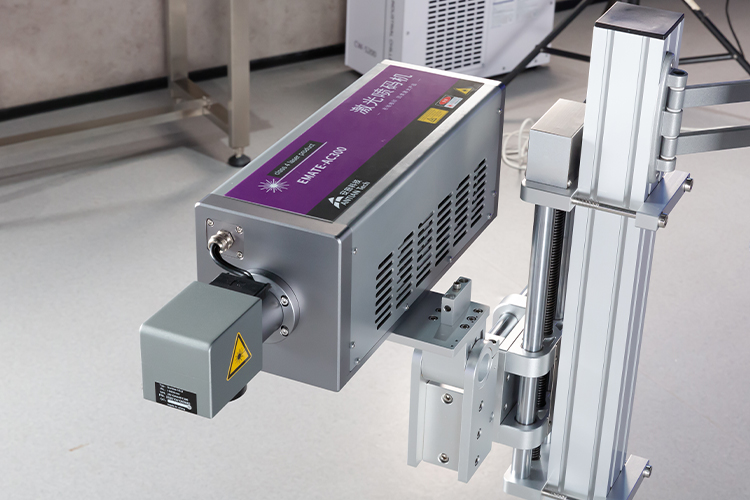

QR code and barcode inkjet printers operate using either continuous inkjet (CIJ) or thermal inkjet (TIJ) technology, each suitable for specific applications depending on speed, substrate type, and desired print quality.

Continuous Inkjet (CIJ):

- How It Works: A constant stream of ink is emitted from a nozzle and charged to form characters. The ink droplets are then deflected by an electric field onto the substrate.

- Best For: High-speed production lines and marking non-porous or curved surfaces such as bottles, cans, and wires.

- Pros: Extremely fast, works on most materials, and offers long operational uptime.

Thermal Inkjet (TIJ):

- How It Works: Tiny resistors heat the ink to form vapor bubbles that propel ink droplets onto the substrate.

- Best For: High-resolution printing on porous and semi-porous materials like paper, cardboard, and certain plastics.

- Pros: Clean, efficient, and environmentally friendly with minimal maintenance.

Workflow Process:

A sensor detects an approaching product.

The controller sends the QR or barcode data to the print head.

The inkjet head ejects ink droplets to form the code.

The code is printed and immediately scanned for quality assurance.

Advanced systems may also include vision inspection modules that verify each code for readability and accuracy post-print.

Benefits of Using a QR Code Automatic Inkjet Printer

The transition to QR code automatic inkjet printers brings a host of benefits, especially for businesses that prioritize traceability, automation, and speed. Here are some of the key advantages:

1. Speed and Efficiency

These printers can handle thousands of products per hour without manual intervention. Their ability to print directly on products as they move along a conveyor belt means no stoppages or downtime due to labeling.

2. Error Reduction

By connecting to databases or ERP systems, each printed code can be validated in real-time, reducing the risk of human error associated with manual data entry and label placement.

3. Real-Time Data Integration

With dynamic printing, codes can reflect the most recent data—like production date, batch number, or serial number—at the moment of printing. This is vital for industries that require real-time traceability.

4. Cost-Effective Operations

Eliminating the need for adhesive labels, ribbons, or pre-printed packaging significantly cuts operational costs over time. It also reduces labor expenses related to manual handling.

5. Customization and Flexibility

Each product can be marked uniquely based on dynamic input, such as serial numbers, production lines, or even marketing campaigns (e.g., QR codes linking to personalized URLs).

6. Sustainability and Waste Reduction

Direct-to-surface printing eliminates label backing waste and reduces material usage, aligning with green manufacturing initiatives.

Common Applications by Industry

The versatility of QR code barcode inkjet printers makes them suitable across a wide spectrum of industries. Let’s explore the most common use cases:

1. Food and Beverage

Date and batch printing directly on bottles, cans, and cartons.

QR codes for consumer engagement (e.g., recipe ideas or brand promotions).

Compliance with traceability requirements in food safety standards.

2. Pharmaceuticals

Serialization of medicine packages to comply with DSCSA and EU FMD regulations.

Anti-counterfeit measures through unique code generation.

Audit trails and recall traceability.

3. Logistics and Warehousing

Print shipping barcodes and QR codes for automated sorting.

Real-time updates to WMS and ERP systems via scanned codes.

Custom code generation for unique customer orders.

4. Manufacturing and Electronics

Marking individual components with part numbers, lot codes, or QR codes for maintenance history.

Compact codes that fit on small electronic components.

5. Consumer Goods and Retail Packaging

Dynamic QR codes that link to installation guides, product registration pages, or loyalty programs.

Seasonal or promotional packaging with variable QR content.

Key Features to Look For in a QR Code Automatic Inkjet Printer

When choosing the right inkjet printer for your business, it's essential to evaluate both the technical specs and compatibility with your existing systems.

1. High Print Resolution

For QR codes to be readable, they must be crisp and well-formed. Look for printers offering 300 to 600 DPI resolution.

2. Substrate Compatibility

Some inkjet printers are better suited to certain surfaces. Choose a printer that can handle your materials (e.g., plastic, glass, metal, cardboard).

3. High Throughput Capability

Ensure that the printer can match your line speed and maintain quality. Look for specs like prints per minute (PPM) or meters per second (MPS).

4. Data Integration and Connectivity

Advanced printers can connect to enterprise systems via Ethernet, Wi-Fi, USB, or RS-232. This enables real-time data printing from a centralized system.

5. Versatile Ink Options

Depending on the application, you might need water-based, solvent-based, or UV-curable inks. The drying time, adhesion, and permanence vary by ink type.

6. User-Friendly Interface

Touchscreen panels, intuitive software, and real-time diagnostics make setup and maintenance easier for operators.

QR Code Standards and Compliance

QR codes and barcodes must adhere to international standards to ensure they are universally scannable and compatible with global supply chains.

Relevant Standards:

- ISO/IEC 18004: Specifies the requirements for QR code encoding and decoding.

- ISO/IEC 15417: Covers Code 128, a common barcode format used in logistics.

- GS1 Standards: Ensures interoperability of barcodes and QR codes used in retail and healthcare.

Using compliant printers ensures that your codes can be read accurately by scanners, smartphones, and automated systems globally.

Future Trends in QR Code and Barcode Inkjet Printing

The landscape of industrial printing is evolving. Here are the top trends to watch:

1. IoT Integration

Printers are increasingly part of smart factory ecosystems. They connect with MES and IoT platforms to automate print adjustments and monitor status remotely.

2. Cloud-Based Control

Cloud printing solutions allow remote management, job scheduling, and firmware updates from any internet-connected device.

3. Sustainable Inks

Development of eco-friendly inks that reduce VOC emissions and enhance workplace safety.

4. Miniaturized Codes

As electronics and medical devices shrink, the demand for micro-printing high-density codes is rising.

5. AI-Driven Quality Control

AI-enabled vision systems can scan each printed code and verify readability instantly, alerting operators of any deviations.

Conclusion

The QR code automatic inkjet printer and its more versatile sibling, the QR code barcode inkjet printer, are transforming the way industries manage product marking, tracking, and compliance. These devices offer unmatched speed, precision, and adaptability, making them indispensable in modern production environments.

By investing in the right printer and implementing best practices, businesses can enhance operational efficiency, reduce errors, and stay competitive in a data-driven market. Whether for internal logistics, customer engagement, or regulatory compliance, these inkjet printers offer scalable and future-proof solutions for any industry.