A Complete Guide to Precision Marking Solutions

Explore both technologies in-depth, outlining their functions, benefits, applications, and how to select the best one for your operational needs.

In today’s highly competitive industrial landscape, clear and durable product identification is not just a necessity—it’s a regulatory and operational mandate. Whether you're labeling parts for traceability, branding products, or printing expiration dates, choosing the right marking technology is critical. Two key technologies dominate this space: the Industrial Laser Marking Machine and the Industrial Laser Printer.

Although sometimes used interchangeably, these tools serve distinct functions and industries. This comprehensive blog explores both technologies in-depth, outlining their functions, benefits, applications, and how to select the best one for your operational needs.

Introduction to Laser Marking and Printing

Laser technology has revolutionized manufacturing by offering permanent, high-speed, and eco-friendly solutions for marking and coding. As companies move away from ink-based systems due to maintenance and environmental concerns, industrial laser marking machines and industrial laser printers have become the go-to solutions.

Both systems leverage high-energy laser beams to inscribe or alter surfaces. The key difference lies in the application:

Industrial Laser Marking Machines are built for deep, permanent marks on raw materials and components.

Industrial Laser Printers are optimized for high-speed, surface-level marking on packaging and fast-moving items.

Understanding their respective strengths will help you make informed, cost-effective decisions that improve traceability, compliance, and product presentation.

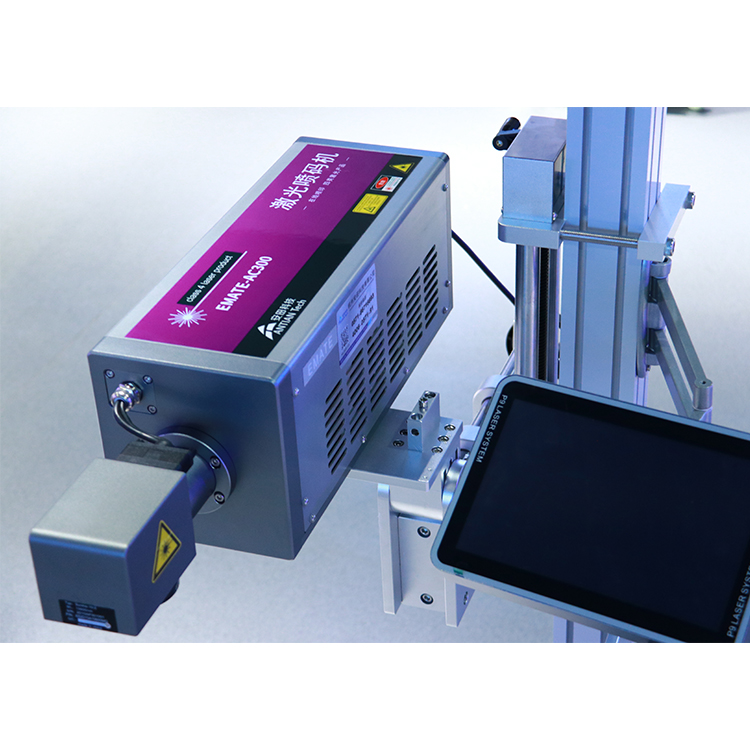

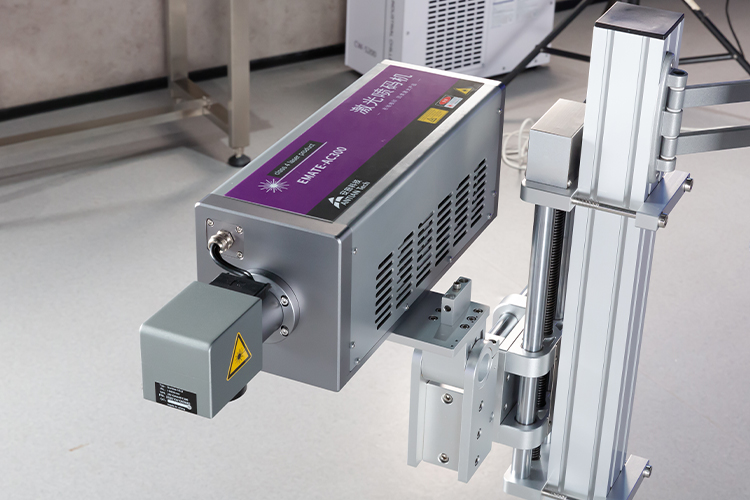

What is an Industrial Laser Marking Machine?

An Industrial Laser Marking Machine is a specialized tool used to create precise, long-lasting marks on various materials. This technology is critical in sectors where product identification, traceability, and anti-counterfeiting are essential.

Working Principle

These machines work by directing a concentrated beam of light onto a surface, altering its physical or chemical structure. The laser’s heat changes the surface without using any inks or chemicals. Depending on the method and material, laser marking can be done through:

- Engraving: The laser removes material to create a recessed mark.

- Etching: A shallow version of engraving, great for thin metals and plastics.

- Annealing: A heat-induced oxidation process that changes color (often on metals like stainless steel) without removing material.

- Foaming: Creates raised marks, primarily on plastics, by heating and bubbling the surface.

- Color Change: In plastics, lasers can shift the pigment, producing high-contrast marks.

Types of Industrial Laser Marking Machines

1. Fiber Laser Marking Machine

Best for marking metals and some plastics

Extremely fine beam for detailed work

Ideal for serial numbers, barcodes, and QR codes

2. CO₂ Laser Marking Machine

Suited for organic materials like wood, leather, acrylic, and paper

Also used in packaging and food industries

Affordable and fast

3. UV Laser Marking Machine

Known for “cold marking” with minimal heat

Excellent for delicate materials like glass and heat-sensitive plastics

Common in electronics, solar panels, and medical packaging

Key Features

High Precision: Micron-level detail is achievable.

Permanent Marks: Resistant to wear, corrosion, heat, and chemicals.

Low Operating Costs: No inks, dies, or solvents required.

Automation Ready: Easily integrated into CNC lines and robots.

Eco-Friendly: No waste or emissions during operation.

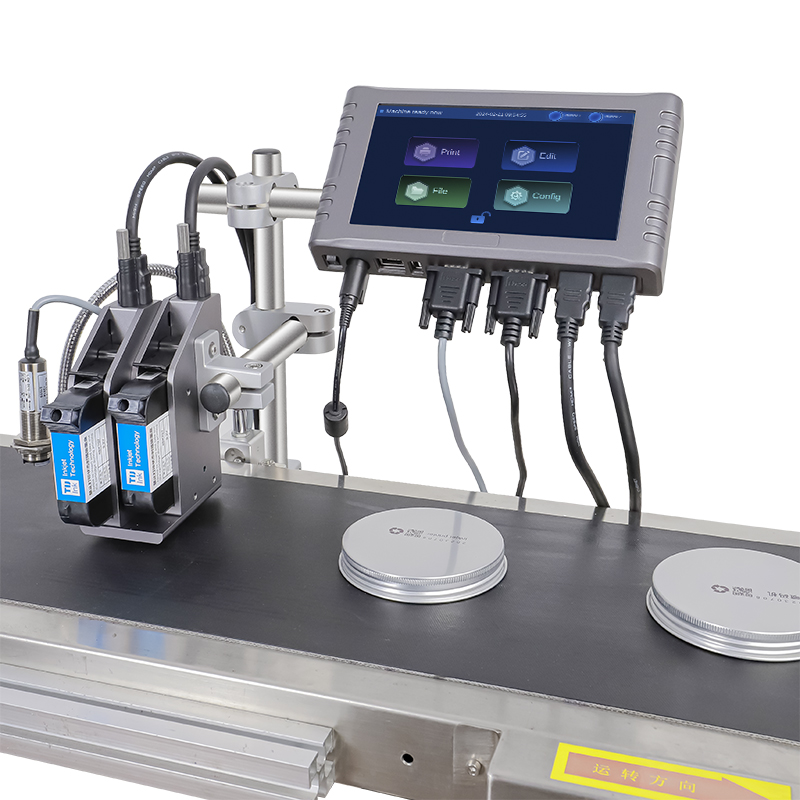

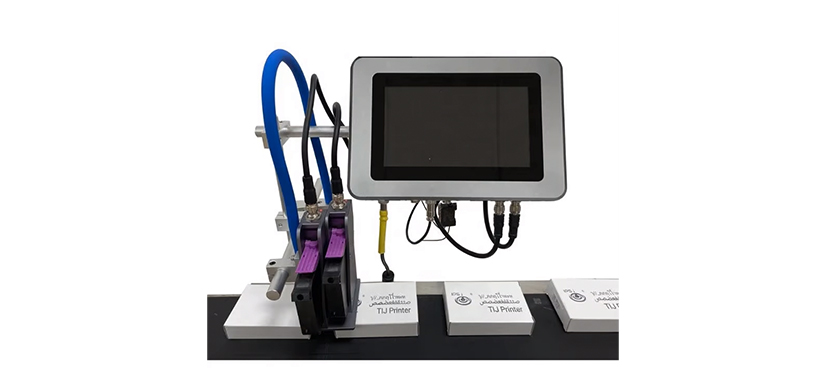

What is an Industrial Laser Printer?

An Industrial Laser Printer is a high-speed laser-based system designed to apply information such as batch numbers, manufacturing dates, expiration dates, and barcodes on finished goods or their packaging.

These printers are ideal for continuous production environments where fast, reliable coding is essential.

Working Principle

Unlike traditional printers that apply ink, laser printers use a focused laser beam to modify the packaging surface. The process is fast, clean, and consistent. Based on the surface, this might involve:

- Ablation: Removing a top layer (e.g., removing ink from a colored label).

- Carbonization: Creating a darkened effect on the substrate.

- Foaming or Surface Melting: Often used on plastics to create contrasting text.

Types of Industrial Laser Printers

1. CO₂ Laser Printers

Ideal for high-speed lines

Used on materials like glass bottles, paperboard cartons, and PET containers

2. Fiber Laser Printers

Best for marking metal lids, aluminum cans, and hard plastics

Compact and maintenance-free

3. UV Laser Printers

Used on soft plastics and labels

Precise and cool operation to avoid damaging thin materials

Key Features

- High-Speed Operation: Can mark up to 1000+ items per minute.

- No Consumables: Reduces operational costs significantly.

- Clean and Dry: No smudging, no drying time required.

- Compact Size: Easily fits on fast-paced production lines.

- Real-Time Coding: Supports variable data (like changing timestamps or product IDs).

Applications Across Industries

Both Industrial Laser Marking Machines and Industrial Laser Printers are used across a wide spectrum of industries. Here’s how they stack up:

Industrial Laser Marking Machine Applications

- Aerospace: Compliance-grade part identification

- Automotive: VIN numbers, engine blocks, dashboard components

- Electronics: Chipsets, circuit boards, connectors

- Medical Devices: Surgical tools, implants, UDI barcoding

- Metal Fabrication: Tool branding, serial numbers, industrial components

- Defense: Traceability and anti-counterfeiting

Industrial Laser Printer Applications

- Food & Beverage: Marking bottles, cans, and flexible packaging with batch codes and expiration dates

- Pharmaceutical: Drug packaging compliance, serialization, and anti-tampering

- Cosmetics: Lot numbers on tubes and containers

- Personal Care Products: Coding lotions, shampoos, and hygiene items

- Electronics: Consumer packaging like chargers, mobile accessories

Industrial Laser Marking Machine vs. Industrial Laser Printer: Key Differences

Understanding the core differences is essential for choosing the right technology:

|

Feature |

Industrial Laser Marking Machine |

Industrial Laser Printer |

|

Primary Use |

Durable product identification |

High-speed packaging and labeling |

|

Marking Type |

Deep, long-lasting, or high-contrast marks |

Surface-level, readable marks |

|

Durability of Mark |

Resistant to wear, water, heat, and solvents |

Sufficient for short-term readability |

|

Speed |

Moderate to high |

Very high (ideal for packaging lines) |

|

Material Compatibility |

Metals, plastics, wood, ceramics |

Plastics, glass, cardboard, paper |

|

System Complexity |

Higher – often integrated with CNC or PLC |

Lower – standalone or line-integrated |

|

Common Industries |

Automotive, aerospace, electronics |

FMCG, pharma, food, and beverages |

Benefits of Laser Technology in Industry

Laser-based systems bring multiple benefits to the table:

No Consumables

Say goodbye to inks, solvents, and ribbons. This not only saves cost but also minimizes storage and waste management.

Permanent Marking

Laser marking is often tamper-proof and survives environmental extremes. This is vital for compliance, recalls, and quality assurance.

Low Maintenance

With no moving ink nozzles or ribbon feeds, lasers have fewer failure points. Most modern machines offer 20,000 to 100,000 hours of operation before maintenance is needed.

Eco-Friendly

Laser systems generate no chemical waste and use less energy overall. They help reduce a company’s environmental footprint and meet sustainability goals.

High Precision and Flexibility

Laser systems can create intricate designs, including microtext, 2D barcodes, and logos. They are programmable for variable data input, adapting on the fly during production.

Frequently Asked Questions (FAQs)

Q1. Can I use the same machine for product marking and packaging printing?

A: In most cases, no. Each system is optimized for a specific task. Laser marking machines focus on durability and component-level markings. Laser printers are built for speed and packaging flexibility.

Q2. Are laser systems safe to use?

A: Yes, when used with proper shielding and safety protocols. Class I or II laser systems are enclosed and safe for industrial use.

Q3. Do laser printers work on curved or uneven surfaces?

A: Yes, with the help of 3D scanners or articulated arms, advanced laser systems can mark complex shapes.

Q4. How expensive are these machines?

A: Entry-level CO₂ laser printers start around $5,000–$10,000. High-end fiber laser marking machines can range up to $100,000+ depending on power, features, and automation.

Q5. What industries benefit most from laser systems?

A: Aerospace, automotive, FMCG, electronics, defense, medical, and manufacturing industries.

Conclusion

As we move toward smarter, cleaner, and more efficient manufacturing systems, both the Industrial Laser Marking Machine and the Industrial Laser Printer play pivotal roles. Their unique capabilities empower industries to meet stringent labeling standards, boost traceability, and enhance product aesthetics.

The key to making the right investment lies in understanding your marking needs:

- Permanent and detailed → Go for an industrial laser marking machine.

- Fast and flexible coding → Choose an industrial laser printer.

Whether you're enhancing traceability in automotive components or adding expiration dates to thousands of soda cans per hour, laser technology offers unmatched reliability, cost-efficiency, and performance.