Continuous Inkjet Printer Manufacturers: A Comprehensive Guide

Discover the leading Continuous Inkjet Printer Manufacturers. Explore top brands, key features, and benefits of CIJ printers for industries like packaging, automotive, and pharmaceuticals. Learn how to choose the right printer for your business needs.

1. Introduction

Continuous inkjet (CIJ) printing is one of the most advanced and widely used printing technologies in industrial and commercial applications. Unlike traditional printing methods that use a print head to transfer ink onto paper or another surface, CIJ printers work by continuously propelling ink droplets onto the substrate, allowing for high-speed and efficient printing. As industries grow, the demand for more precise, faster, and cost-effective printing solutions has surged, giving rise to the growth of continuous inkjet printers in various sectors such as packaging, food and beverage, pharmaceuticals, and automotive industries.

In this article, we will explore the continuous inkjet printer manufacturers, their key offerings, and how businesses can benefit from these printers. We'll also cover important considerations for those looking to purchase a continuous inkjet printer for sale, providing a detailed overview of available options and factors to consider.

2. Types of Continuous Inkjet Printers

Continuous inkjet printers are versatile tools that can be classified into various types depending on the application, resolution, and speed. The right printer depends on the unique requirements of the production environment.

High-Resolution CIJ Printers

High-resolution CIJ printers are designed to deliver superior quality prints. These printers use fine droplet technology, making them ideal for applications that require small fonts, logos, barcodes, and QR codes. Industries such as electronics, pharmaceutical packaging, and consumer goods manufacturing rely heavily on high-resolution CIJ printers to ensure product traceability and compliance with regulatory standards.

Key Features:

-

High DPI (Dots Per Inch): Capable of printing detailed graphics, logos, and small text with crisp quality.

-

Fast Drying Inks: Ideal for printing on various materials such as plastic, glass, and metal without smudging.

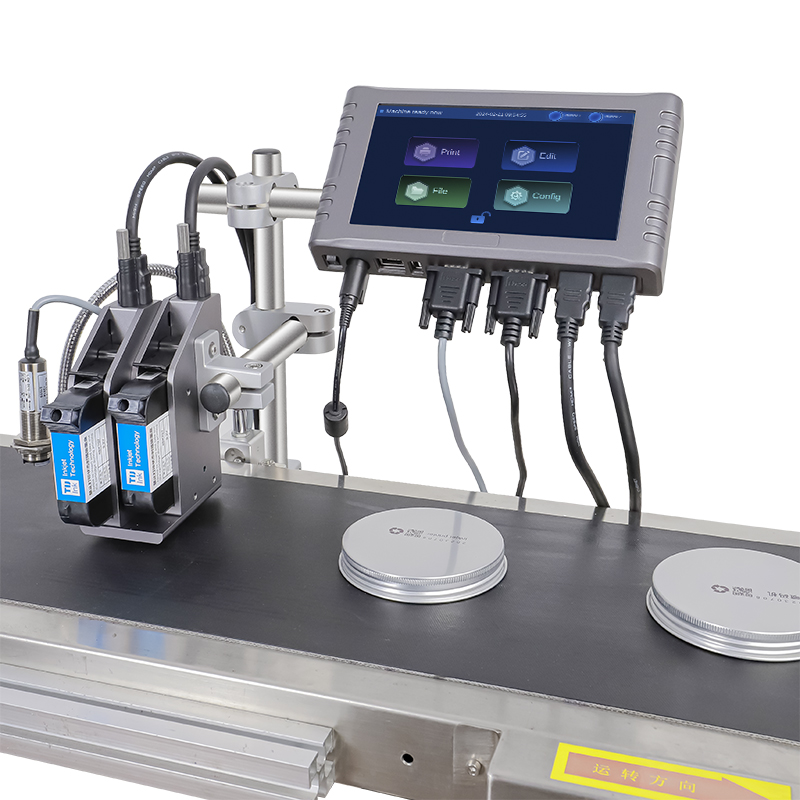

Industrial CIJ Printers

Industrial CIJ printers are built to withstand tough working conditions and are engineered for high-volume printing. These printers are typically used in larger production environments where high durability and reliability are critical. They are ideal for marking large quantities of products and can print at a high speed, which is essential in manufacturing lines.

Key Features:

-

Durability: These printers are built to last, with rugged components that can survive harsh environments.

-

High-Speed Printing: Capable of printing hundreds or thousands of products per minute.

-

Long-Lasting Printheads: Designed to handle high workloads without frequent replacement.

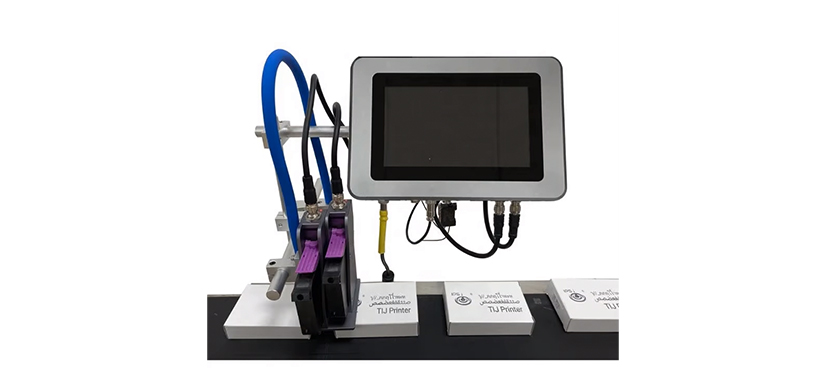

Low-Cost CIJ Printers

Low-cost CIJ printers provide an entry-level solution for small to medium-sized businesses. These printers offer a more budget-friendly option for companies that need high-speed and efficient printing but don’t require the robust features of industrial printers. These machines are great for businesses in the food industry, cosmetics, or small manufacturing setups that need reliable coding and marking without breaking the bank.

Key Features:

-

Affordability: More affordable than industrial models while still offering excellent functionality.

-

Ease of Use: User-friendly interfaces and reduced maintenance make them ideal for smaller companies.

-

Compact Size: These printers are often more compact, fitting into smaller production spaces.

3. Key Features of Continuous Inkjet Printers

When choosing a continuous inkjet printer, businesses should consider several factors that can impact performance, efficiency, and overall cost-effectiveness. Below are the primary features of CIJ printers that make them essential in modern manufacturing environments.

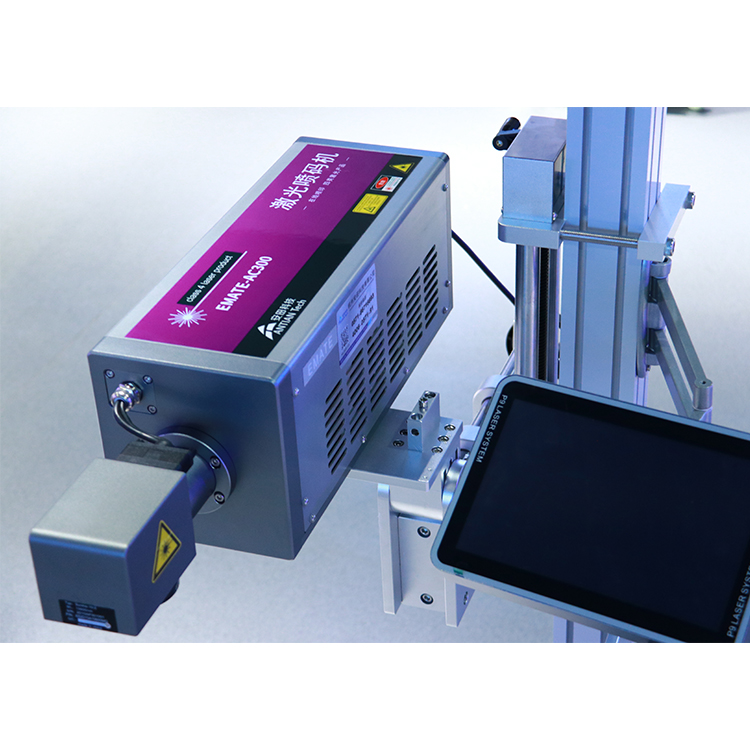

Print Quality and Resolution

Print quality is one of the most important aspects of CIJ printers. With continuous inkjet technology, manufacturers can achieve high-quality, sharp, and durable prints. The resolution of CIJ printers varies, but the best models offer a minimum resolution of 300 dpi, which is suitable for printing fine text, logos, and complex barcodes.

High-resolution CIJ printers can provide up to 600 dpi, which is essential in industries like pharmaceuticals, where precise labeling is mandatory. These printers can also produce high-contrast prints on a variety of materials, ensuring that the printed data is readable even after exposure to environmental factors such as moisture, sunlight, or abrasion.

Speed and Efficiency

CIJ printers are known for their speed. With their ability to print continuously, these printers can produce hundreds or even thousands of prints per minute without interruption. This makes them ideal for high-volume production lines in industries such as food packaging, automotive manufacturing, and electronics.

The speed of a CIJ printer is determined by its printhead size and ink delivery system. Modern CIJ printers can operate at speeds of up to 1000 meters per minute, ensuring that production lines can keep up with the pace of modern manufacturing.

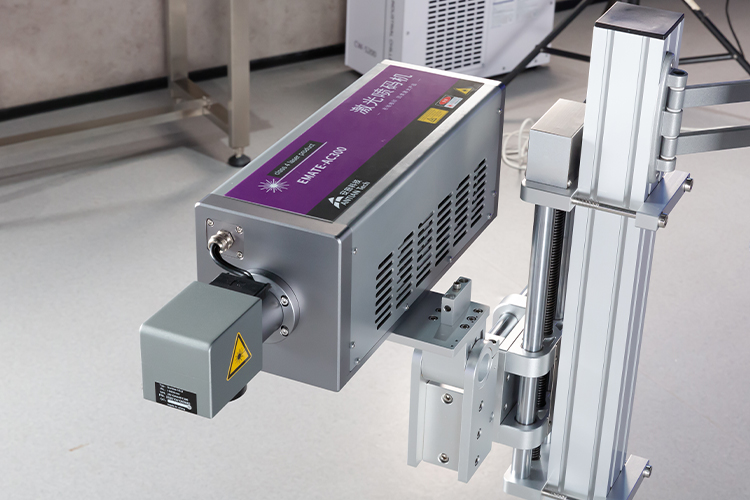

Durability and Maintenance

Durability is another key feature of CIJ printers. Many industrial-grade CIJ printers are designed to work in challenging environments, including extreme temperatures, humidity, and exposure to chemicals. The printheads are constructed for long-lasting performance, and the ink systems are designed to reduce clogging, which is a common problem with older CIJ printers.

Maintenance is typically low, with many models featuring automatic cleaning systems to reduce downtime and prevent ink from drying inside the printer. Some printers also offer remote diagnostics and monitoring to ensure that the printer is functioning at peak efficiency.

Ink Types and Compatibility

Continuous inkjet printers are compatible with various ink types, including solvent-based, water-based, and UV inks. The choice of ink depends on the application and the material being printed on.

-

Solvent-based inks: Used for printing on non-porous surfaces such as plastics, metals, and glass.

-

Water-based inks: Ideal for porous surfaces like cardboard, paper, and textiles.

-

UV inks: Used for printing on materials that require resistance to UV light, such as plastic packaging and labels.