Handheld Laser Marking Machine Advantages Every Manufacturer Should Know

Explore the advantages of a Handheld Laser Marking Machine for modern manufacturers. Learn how it improves precision, efficiency, material versatility, and creative applications across industries.

In today’s fast-paced manufacturing environment, precision, efficiency, and flexibility are key. The Handheld Laser Marking Machine has emerged as a revolutionary tool for manufacturers, offering unmatched advantages in product identification, branding, and traceability. From small-scale workshops to large industrial production lines, these devices are transforming how companies approach marking and engraving. This article explores the technology, benefits, applications, and future trends of Handheld Laser Marking Machines, providing a comprehensive guide for manufacturers.

Understanding How a Handheld Laser Marking Machine Works

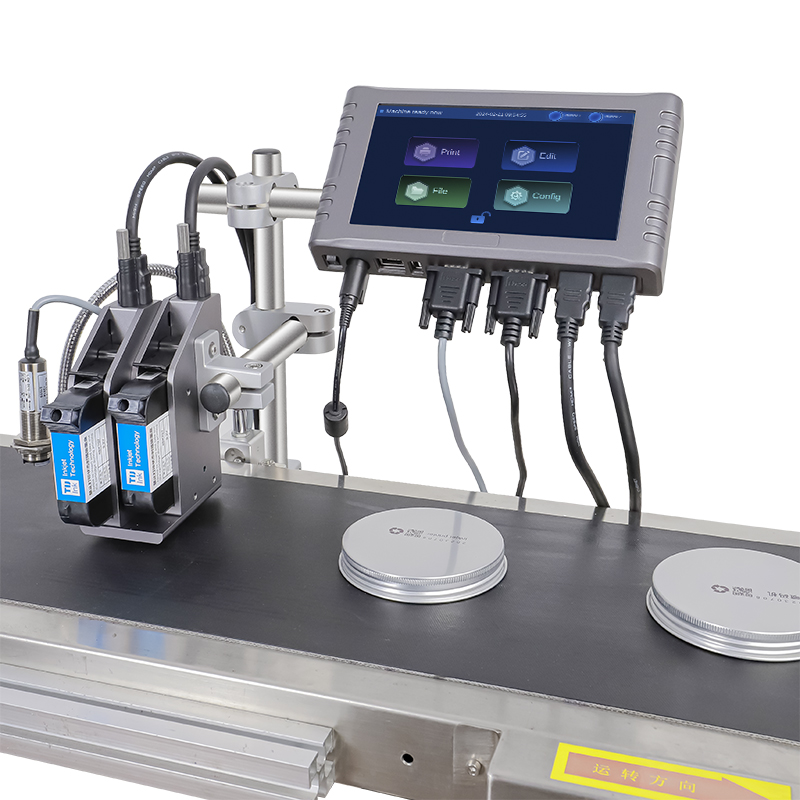

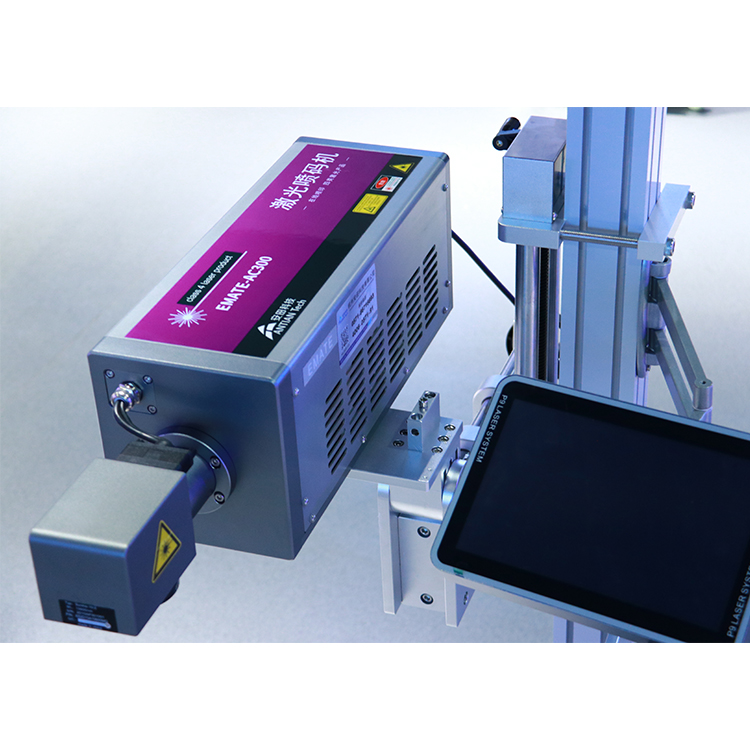

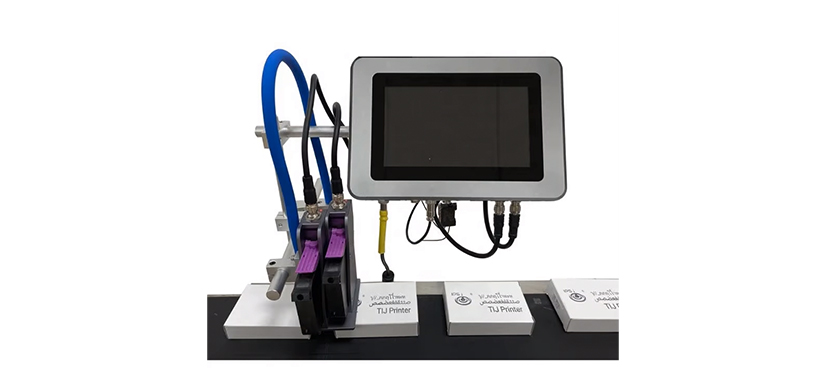

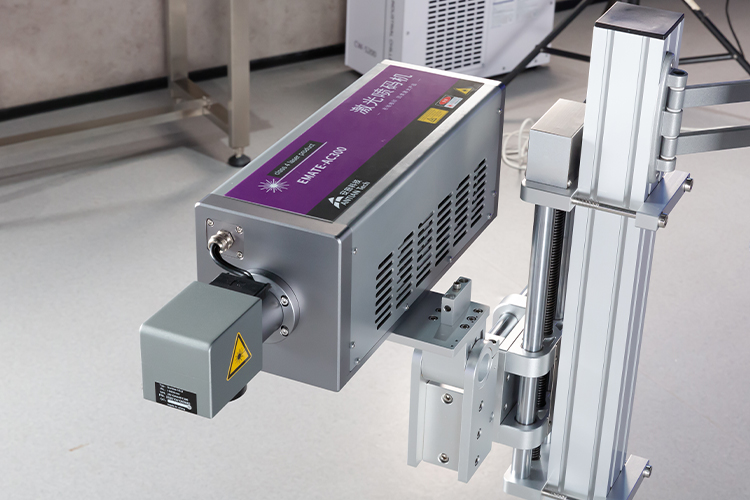

A Handheld Laser Marking Machine uses a focused laser beam to create permanent marks on various materials. Unlike traditional marking methods that rely on mechanical contact or chemical processes, laser marking is contactless, precise, and clean.

The basic working principle involves directing a laser beam onto a surface to either engrave, etch, or change the material’s color. The process is controlled via software, allowing for high accuracy, complex patterns, serial numbers, logos, or barcodes.

Advantages of this technology include:

- Precision – The laser beam can focus on very small areas, producing detailed patterns.

- Speed – High-speed scanning enables rapid marking without slowing production.

- Durability – Marks are resistant to wear, chemicals, and heat, ensuring long-lasting visibility.

Manufacturers benefit from Handheld Laser Marking Machines because they can integrate marking directly into production lines without slowing workflow, improving both quality and efficiency.

Key Benefits of Using a Handheld Laser Marking Machine in Manufacturing

Handheld Laser Marking Machines offer multiple benefits that make them indispensable in modern manufacturing:

- High Accuracy – Capable of marking extremely small details with minimal error.

- Versatility – Suitable for metals, plastics, ceramics, glass, and even composite materials.

- Portability – Handheld design allows operators to move freely and mark large or irregular objects.

- Reduced Operational Costs – No consumables like ink or chemicals are needed.

- Quick Setup – Software-controlled operations minimize training time and setup complexity.

These advantages allow manufacturers to increase productivity, reduce errors, and deliver consistent, high-quality products.

Material Compatibility of Handheld Laser Marking Machines

One of the most significant strengths of a Handheld Laser Marking Machine is its ability to work on a wide variety of materials. Key examples include:

|

Material Type |

Applications |

Advantages |

|

Metals |

Electronics, automotive parts, tools |

Durable, precise, corrosion-resistant marks |

|

Plastics |

Packaging, consumer products, medical devices |

No surface damage, fast and flexible |

|

Glass |

Bottles, jars, decorative items |

Clean engraving, aesthetic appeal |

|

Ceramics |

Tiles, industrial components |

Heat-resistant and permanent markings |

|

Composites |

Aerospace, automotive panels |

Marks without weakening material structure |

This versatility enables manufacturers to use a single device across multiple production lines, reducing equipment costs while maintaining quality and consistency.

Cost Efficiency and Productivity Gains with Handheld Laser Marking Machines

Investing in a Handheld Laser Marking Machine provides long-term cost savings and productivity improvements.

- Lower Consumable Costs – Unlike traditional ink-based systems, lasers require no inks, solvents, or ribbons.

- Faster Production – Immediate marking reduces bottlenecks and increases throughput.

- Reduced Waste – On-demand marking eliminates overproduction of pre-printed labels.

- Multi-Function Use – Engraving, etching, and barcoding can all be done on one device.

Manufacturers often report a significant return on investment within months due to reduced material waste, labor efficiency, and improved product quality.

Creative Applications in Industrial Design Using Handheld Laser Marking Machines

Beyond basic product marking, Handheld Laser Marking Machines enable creative industrial design possibilities:

- Custom Logos and Branding – Add unique branding to products without additional packaging.

- Serial Numbers and Traceability Codes – Essential for quality control and regulatory compliance.

- Decorative Effects – Laser engraving can create textures, patterns, and 3D designs for premium products.

- Prototyping – Engineers can quickly mark prototypes for testing and identification.

By integrating creative design elements directly onto products, manufacturers can differentiate their offerings and provide a higher perceived value.

Safety and Maintenance Tips for Handheld Laser Marking Machines

Operating a Handheld Laser Marking Machine safely is critical to protect users and ensure longevity of the equipment:

- Eye Protection – Always use protective goggles to avoid eye damage from laser exposure.

- Ventilation – Marking certain materials may produce fumes; ensure proper ventilation.

- Regular Cleaning – Keep laser lenses and surfaces free from dust and debris.

- Software Updates – Regularly update firmware to improve precision and functionality.

- Proper training and maintenance not only ensure safety but also maintain consistent marking quality over time.

Comparing Handheld Laser Marking Machines with Traditional Marking Methods

Traditional marking methods such as screen printing, embossing, and hot stamping have limitations compared to Handheld Laser Marking Machines.

|

Feature |

Traditional Methods |

Handheld Laser Marking Machine |

|

Precision |

Medium |

High, even for intricate patterns |

|

Speed |

Slower, requires setup |

Rapid, minimal setup required |

|

Material Range |

Limited |

Metals, plastics, glass, ceramics, composites |

|

Durability |

Can fade or wear |

Long-lasting, chemical and heat resistant |

|

Cost |

Recurring consumables |

One-time investment, low operating cost |

This comparison highlights why many manufacturers are replacing older marking technologies with handheld laser solutions.

Future Trends and Innovations in Handheld Laser Marking Machines

The future of Handheld Laser Marking Machines is bright, with emerging trends shaping the next generation of industrial marking:

- Automation Integration – Smart factories will integrate handheld lasers into automated production lines.

- IoT Connectivity – Laser marking devices connected to the cloud for monitoring, analytics, and predictive maintenance.

- Advanced Materials – Development of lasers compatible with more exotic materials, enabling new product designs.

- Smart Marking – QR codes, NFC, and AR-enabled designs embedded directly onto products.

These innovations ensure that handheld laser marking remains at the forefront of industrial technology, providing manufacturers with both efficiency and creativity.

FAQ

Q1: Can a Handheld Laser Marking Machine work on any surface?

A: Most handheld laser marking machines work on metals, plastics, glass, ceramics, and composites, but very soft or flexible surfaces may require testing.

Q2: Is handheld laser marking safe for operators?

A: Yes, if proper protective measures are followed, including eye protection and ventilation.

Q3: How does handheld laser marking improve production efficiency?

A: It reduces setup time, eliminates consumables, and allows on-demand marking, speeding up the manufacturing process.

Q4: What maintenance is required for a handheld laser marking machine?

A: Regular lens cleaning, software updates, and routine calibration ensure consistent performance and longevity.