How UV Inkjet Printers Are Transforming Packaging and Product Labeling

Discover how UV inkjet printers are revolutionizing packaging and product labeling. Learn about their benefits, applications, and why businesses are switching to UV printing for efficiency, branding, and sustainability.

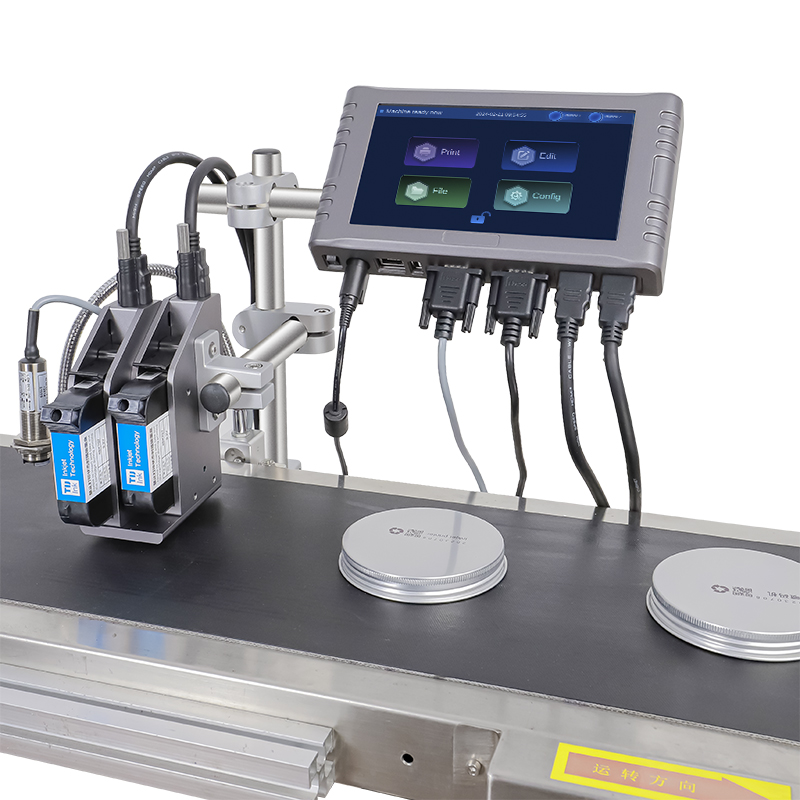

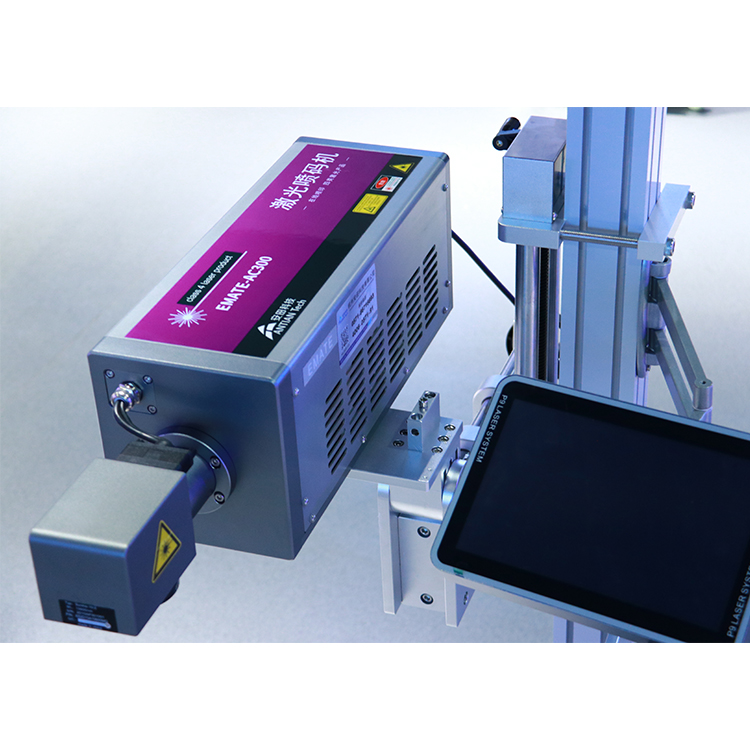

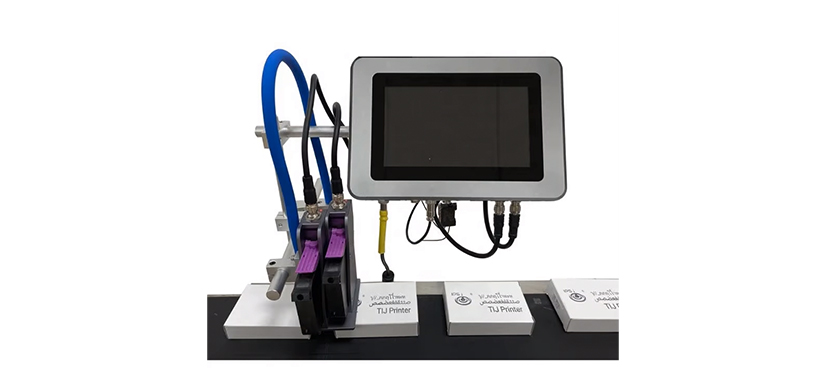

1. What Is a UV Inkjet Printer and How Does It Work in Packaging?

A UV inkjet printer is a digital printing device that sprays liquid ink directly onto a surface and instantly cures it using ultraviolet light. Unlike traditional printing, which requires drying time or pre-treatment, UV curing hardens the ink almost immediately. This allows packaging manufacturers to print directly on materials such as plastics, glass, metals, cartons, and films. For product labeling, this means sharp, durable graphics without smudging or fading. In the packaging world, the ability to print directly on different substrates is a game-changer because it eliminates the need for labels, stickers, or additional coatings.

2. Key Advantages of Using a UV Inkjet Printer for Product Labeling

- A UV inkjet printer offers several critical advantages:

- High resolution and clarity: Perfect for small text, barcodes, and brand logos.

- Fast curing and productivity: Since the ink cures instantly, production lines don’t slow down.

- Durability: UV inks resist water, heat, and scratches, ensuring labels remain intact during storage and shipping.

- Flexibility: From large packages to fine product labels, UV printers adapt easily.

These advantages make UV inkjet technology the preferred choice for manufacturers seeking to improve product traceability, branding, and compliance without compromising efficiency.

3. UV Inkjet Printer Applications Across Different Packaging Materials

- One of the strongest advantages of a UV inkjet printer is its ability to print on a wide range of surfaces:

- Plastics: Used in beverage bottles, cosmetics containers, and food trays.

- Glass: Ideal for luxury packaging, perfumes, or premium drinks.

- Cardboard & Paperboard: Widely used in folding cartons and retail packaging.

- Flexible Films: Perfect for snack bags, medical pouches, and flow wraps.

- Metals: Used for automotive parts packaging or industrial labels.

By offering multi-material compatibility, UV printers simplify operations for packaging companies that deal with diverse product lines.

4. How a UV Inkjet Printer Improves Brand Visibility Through Packaging

Modern consumers expect packaging to be not just functional but also visually appealing. A UV inkjet printer enables brands to achieve:

- Vibrant, full-color graphics that stand out on shelves.

- High customization, allowing brands to run personalized or seasonal designs without retooling.

- Premium finishes, including matte or gloss effects, directly integrated into the package.

This ability to merge durability with design creates packaging that not only protects products but also attracts attention and communicates brand value.

5. The Role of UV Inkjet Printers in Sustainable Packaging Solutions

Sustainability is a pressing concern in packaging. A UV inkjet printer supports greener production in several ways:

- Low waste: Digital printing eliminates the need for plates or screens.

- Reduced chemicals: No solvents or extra coatings are required.

- Eco-friendly inks: Many UV inks are low-VOC and designed for environmental compliance.

- Direct-to-surface printing: Eliminates labels, adhesives, and additional packaging layers.

For brands under pressure to reduce environmental impact, UV technology provides a practical step toward more sustainable packaging.

6. UV Inkjet Printer vs Traditional Labeling Methods: A Clear Comparison

Traditional labeling often relies on stickers, thermal transfer, or flexographic printing. While effective, these methods involve higher costs for consumables, limited design flexibility, and slower changeover times. A UV inkjet printer, by contrast:

- Prints directly on packaging, eliminating labels.

- Handles short and long runs equally efficiently.

- Delivers superior image quality with minimal preparation.

- Reduces overall production costs by cutting down consumables and labor.

For businesses competing in fast-moving industries, this shift in efficiency can be a major strategic advantage.

7. Why UV Inkjet Printers Are Ideal for Variable Data Printing

Variable data printing is crucial for industries like food, pharmaceuticals, and electronics. A UV inkjet printer excels at printing unique codes, batch numbers, expiry dates, QR codes, and barcodes on every single package. This ensures compliance with regulations while supporting advanced functions like traceability, anti-counterfeiting, and supply chain visibility. The ability to print precise, high-speed, variable data directly on packaging sets UV printers apart from most traditional solutions.

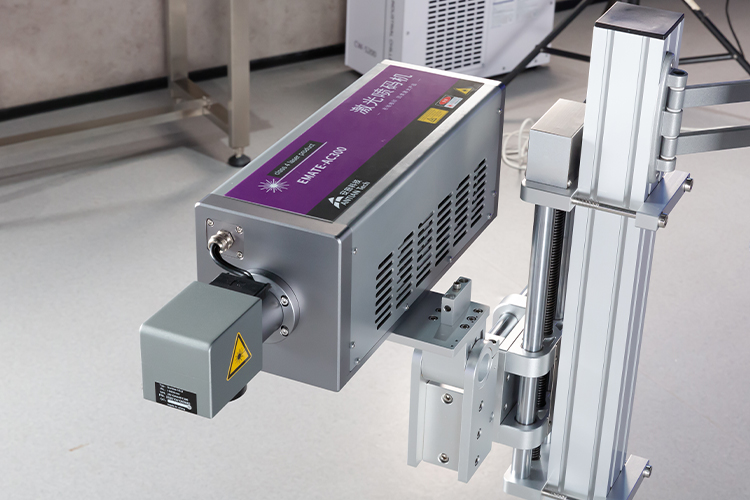

8.Choosing the Right UV Inkjet Printer for Your Packaging Line

Not all UV printers are the same. When selecting a UV inkjet printer, businesses should consider:

- Print speed and resolution (for high-volume vs detailed printing).

- Material compatibility (does it match your substrates?).

- Integration with existing conveyor systems or automation.

- Ink cost and sustainability.

- Software and variable data capabilities.

Making the right choice ensures seamless adoption and maximized ROI for packaging operations.