How Packaging Coding Printer Factories Customize Solutions for High-Speed Production Lines

Learn how a Packaging Coding Printer factory customizes coding systems for high-speed production lines. Discover why choosing the right Packaging Coding Printer supplier improves accuracy, efficiency, and long-term reliability.

In today’s fast-paced manufacturing environment, high-speed production lines require printing systems that are accurate, durable, and fully adaptable to different packaging materials. This is where a professional Packaging Coding Printer factory plays a vital role. Unlike standard off-the-shelf printers, factory-level customization ensures that each coding system fits the exact speed, production environment, and packaging type of a customer’s line.

Understanding Customer Requirements From the Production Line

A reputable Packaging Coding Printer factory begins every customization project by evaluating the customer’s production line. This process helps the manufacturer understand what printing challenges need to be solved.

Typical factors assessed include:

- Production speed and line layout

- Packaging materials (plastic, metal, glass, paper, film, etc.)

- Required coding type (date, batch number, QR code, barcodes)

- Environmental conditions (dust, humidity, temperature)

By gathering this information, the factory can design a solution that is fast, stable, and compatible with the customer’s workflow.

Tailoring Printer Technology for High-Speed Output

High-speed production lines need printers that can deliver precise, readable codes without slowing down operations. A professional Packaging Coding Printer factory tailors its printing technology based on the line’s performance requirements.

Common customized technologies include:

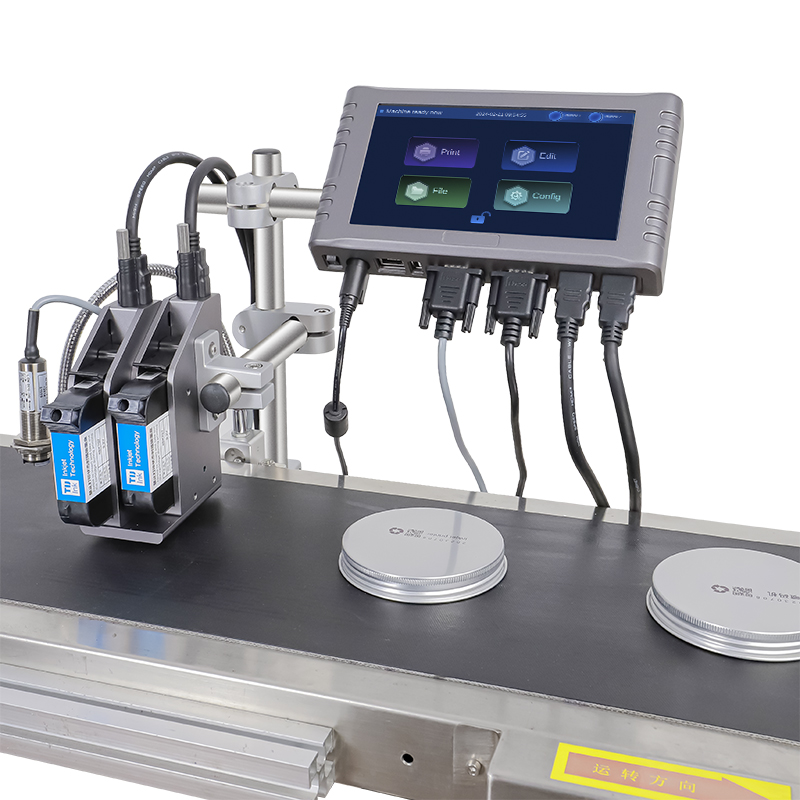

- High-speed inkjet systems for continuous production

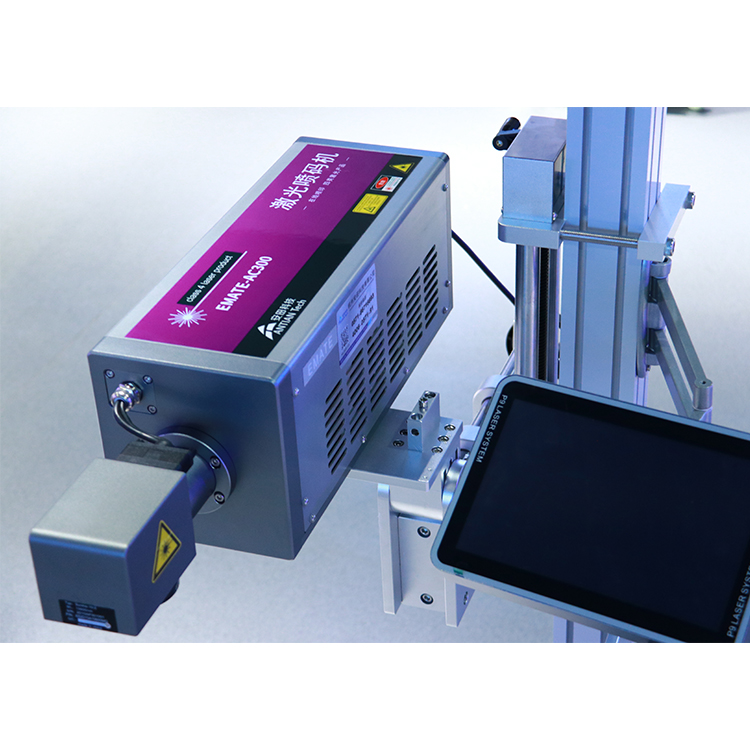

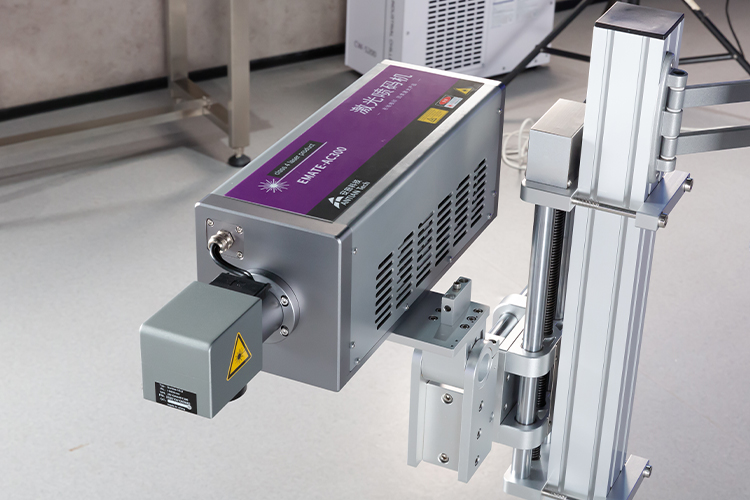

- Laser coding printers for fast and permanent marking

- Thermal transfer overprinters (TTO) for flexible packaging

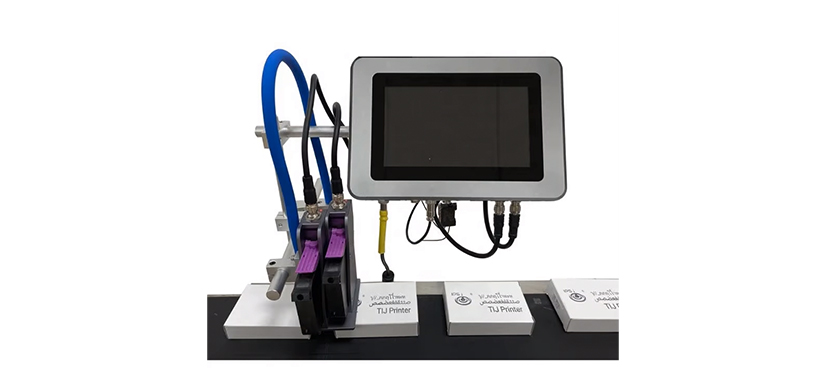

- High-resolution inkjet (TIJ) systems for fine-text printing

Each technology has strengths, and customization ensures the printer runs smoothly even at maximum speed.

Custom Integration and Mounting Solutions

One advantage of working with an experienced Packaging Coding Printer supplier is the ability to receive fully customized mounting systems. High-speed lines often have limited space, and printing heads must be positioned precisely to achieve readable codes.

A Packaging Coding Printer factory typically customizes:

- Mounting brackets and adjustable stands

- Conveyor belt synchronization modules

- Auto-sensing print triggers

- Multi-head systems for simultaneous printing on different surfaces

This ensures stable, vibration-free performance at high speeds.

Software Customization for Efficient Coding Management

For high-volume production lines, software plays a crucial role. A Packaging Coding Printer factory often develops or customizes software to meet a customer’s operational needs.

Key customization features include:

- User-friendly interfaces for quick message edits

- Integration with ERP or MES systems

- Automatic data updates (dates, batch numbers, serials)

- Multi-line coordination and monitoring dashboards

These custom software options help operators manage coding tasks more easily, reduce errors, and improve efficiency.

Optimizing Ink and Consumables for Different Packaging Materials

Not all inks work the same on high-speed production lines. When working with a knowledgeable Packaging Coding Printer supplier, customers can request custom ink formulations based on their packaging type and environmental needs.

Custom ink options may include:

- Fast-drying inks for rapid conveyor speeds

- High-contrast inks for dark packaging

- Solvent-resistant inks for harsh environments

- Food-safe inks for food and pharmaceutical packaging

By supplying optimized consumables, the Packaging Coding Printer factory ensures reliable, high-quality prints even at top speeds.

Testing and Calibration Within Real Production Conditions

A key step that sets a professional Packaging Coding Printer factory apart is the testing phase. Manufacturers simulate real working conditions to test print speed, stability, and clarity.

This process involves:

- High-speed print trials

- Durability and smudge resistance testing

- Long-duration reliability tests

- On-site calibration at the customer’s facility

Only after passing these tests is the printer approved for delivery.

Ongoing Support From a Trusted Packaging Coding Printer Supplier

Customization doesn’t end after installation. A reliable Packaging Coding Printer supplier provides continuous technical support, maintenance services, and spare parts supply. This ensures long-term stability, especially for 24/7 production environments.

Ongoing services may include:

- Remote troubleshooting and software updates

- Technician training programs

- Preventive maintenance visits

- Quick delivery of consumables and components

This long-term partnership helps production lines maintain consistent printing quality and minimize downtime.

Final Thoughts

High-speed production lines demand more than a standard coding printer and they require a tailored solution built for speed, precision, and durability. By working with an experienced Packaging Coding Printer factory and a reliable Packaging Coding Printer supplier, businesses can achieve smoother operations, higher print consistency, and reduced maintenance costs. Custom-built coding systems ensure that every product is properly marked without slowing down the production process, making them essential for modern manufacturing.