How a High-Tech CO2 Laser Marking Machine Factory Ensures Quality Control

Discover how a high-tech CO2 Laser Marking Machine factory guarantees precision and reliability through strict quality control. Choose the right supplier with confidence.

For any CO2 Laser Marking Machine factory, the most important thing is to ensure stable, reliable, and high-precision performances. With growing global demand for non-metal marking solutions, customers are expecting machines that deliver excellent quality of markings, long service life, and continued performance. Therefore, to meet such demand, modern factories have employed advanced production technologies, strict quality inspections, and international-grade testing procedures.

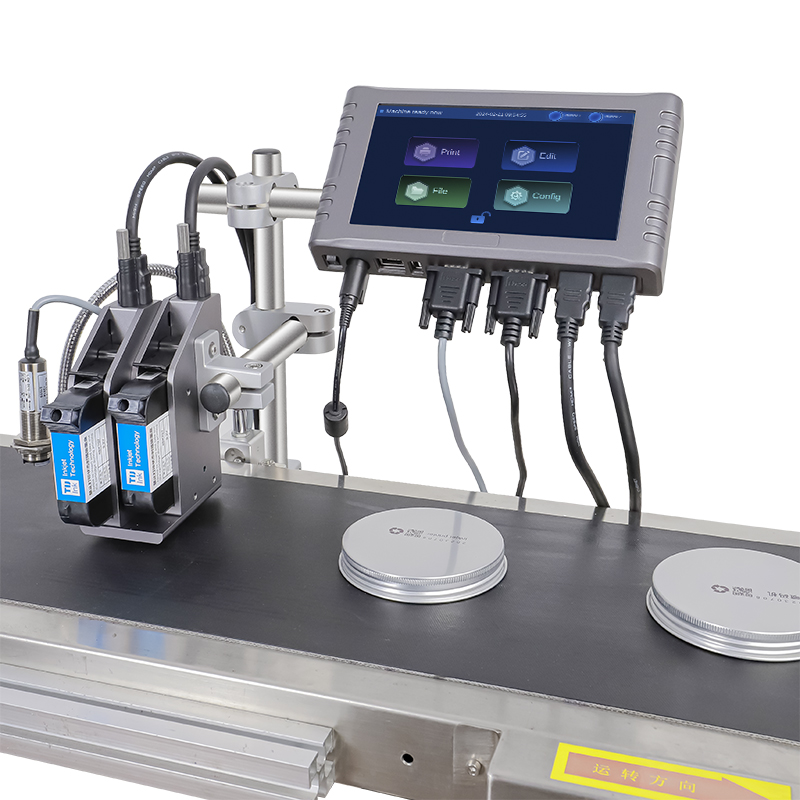

Advanced Production Facilities in a Modern CO2 Laser Marking Machine Factory

Generally speaking, a decent CO2 Laser Marking Machine factory usually runs under high automation and digital management. It would have big investments in CNC machining centers, automatic welding, dust-free assembly room, and precision calibration system.

Precision CNC manufacturing ensures that machine components meet tight tolerances.

Industrial-grade optical alignment systems ensure stable laser output.

Clean assembly environments prevent contamination of optical components, which is very important for consistent performance in lasers.

Advanced infrastructure of this sort enables the factory to support stable production quality, ensure large-volume orders, and fulfill customized OEM/ODM projects.

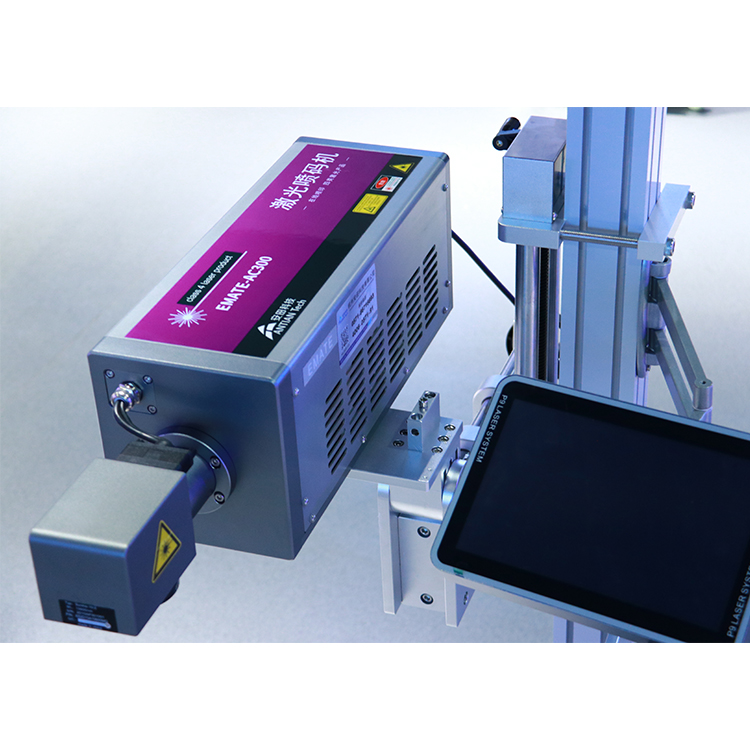

Strict Component Selection from Top-Level CO2 Laser Marking Machine Suppliers

Quality control starts long before the assembly process. A professional CO2 Laser Marking Machine supplier has to be careful in selecting components from well-recognized manufacturers. Main components like RF CO2 laser tubes, galvanometer scanners, power supplies, and control boards directly affect marking quality and machine service life.

A high-tech supplier will routinely:

- Source RF CO2 laser tubes from industry-recognized brands with proven stability.

- High-resolution galvanometer scanners ensure the most accurate and fast marking.

- Implement industrial power systems possessing stable current output and safety protection.

Only components passing inspection at the point of entry make their way into a production line to guarantee each machine has sound beginnings.

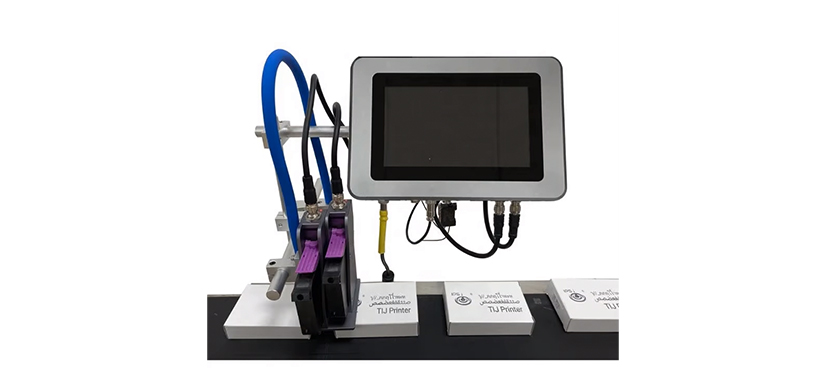

Standardized Assembly Process Ensures Consistency

Inside a professional factory, assembly is carried out in accordance with a standardized workflow for the CO2 Laser Marking Machine to avoid human errors and keep homogeneity among the units.

The key steps include:

- Mechanical installation using jigs and fixtures to ensure exact positioning.

- Focusing and calibration of optics for optimal laser beam quality.

- Checks on electrical wiring to prevent short-circuits or overheating.

- Software configuration allows for tailoring marking parameters to each machine model.

Every technician is trained on ISO-aligned procedures to ensure each machine is built to the same technical standard.

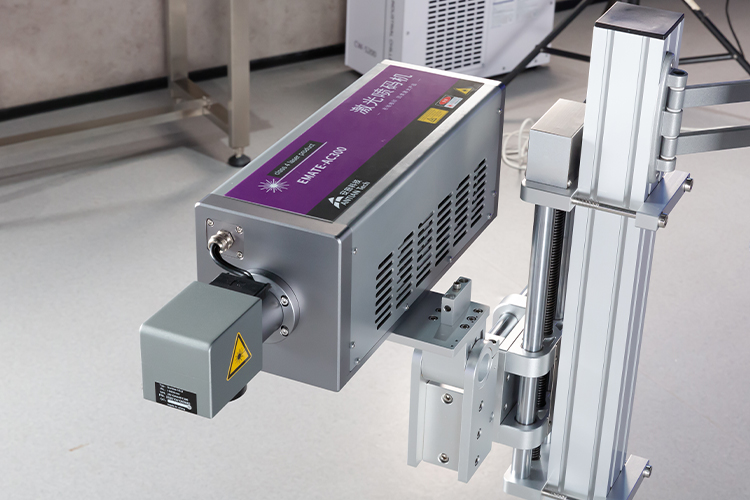

Multi-Stage Testing to Guarantee Reliable Performance

Testing is the heart of quality control. A high-tech CO2 Laser Marking Machine supplier will perform several rounds of inspections before shipping:

Performance Testing

The machine should be analysed for the stability of the laser output, clarity of marking, precision of the line, and marking speed.

Durability & Continuous Running Tests

The machines work for 8–24 hours continuously to ensure their performance in real working conditions.

Material Compatibility Tests

The factory tests the performance of marking on multiple materials: leather, wood, acrylic, paper, and plastic.

Electrical Safety Checks

Voltage stability, grounding resistance, and emergency-stop systems are tested to meet international safety standards.

Only those machines that have passed all testing phases are approved for packaging.

Quality Documentation and Traceability System

To enhance transparency and accountability, a modern CO2 Laser Marking Machine factory uses a digital traceability system. Each machine receives a unique serial number linked to:

- Component batch records

- Assembly operator

- Testing results

- Firmware version

- After-sales service history

This system allows customers to track product origin and helps the factory deliver efficient after-sales support.

Professional After-Sales Support From a Trusted CO2 Laser Marking Machine Supplier

Quality control does not end when the machine leaves the factory. Leading suppliers provide ongoing support, including:

- Online installation guidance

- Remote troubleshooting

- Spare part supply

- Software updates

- Technical training

Strong after-sales service enhances customer experience and reflects the internal confidence a factory has in its product quality.