What an Industrial UV Laser Marker Is and Why Supplier Selection Matters

Learn what an Industrial UV laser marker is and why choosing the right Industrial UV Laser Marker supplier or factory is crucial for precision, durability, and stable production.

Industry manufacturing has continuously demanded higher precision, cleaner markings, and the ability to mark a wider range of materials with minimal or no thermal damage. Among all laser marking technologies, the Industrial UV laser marker has gained increasing trust as a solution for high-accuracy and micro-marking applications. The UV laser marking technique provides unparalleled detail and stability, be it in electronics, medical devices, automotive components, or packaging.

But it is rather crucial to select the proper Industrial UV Laser Marker supplier or the correct Industrial UV Laser Marker factory. The performance, lifespan, and long-term reliability of your equipment depend heavily on the manufacturer's expertise and quality standards.

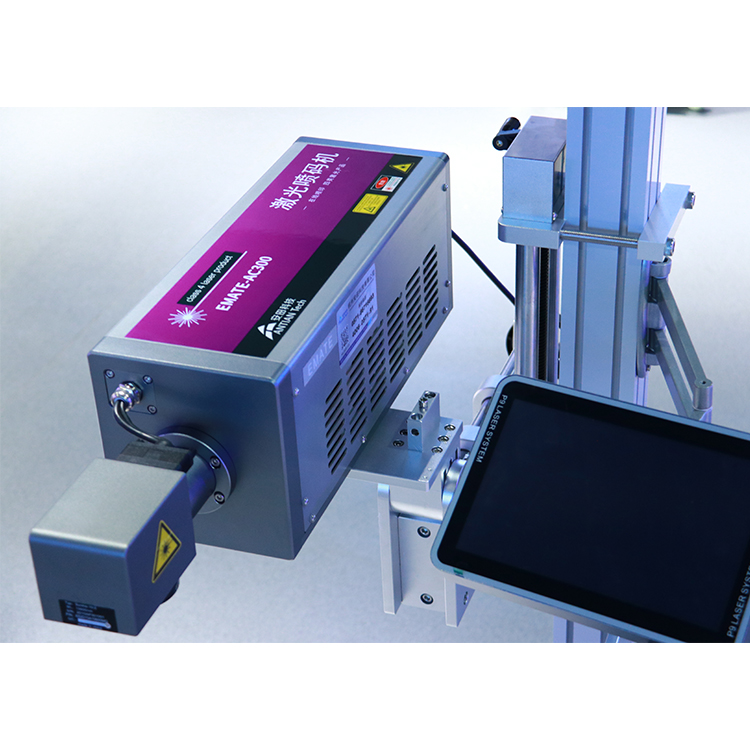

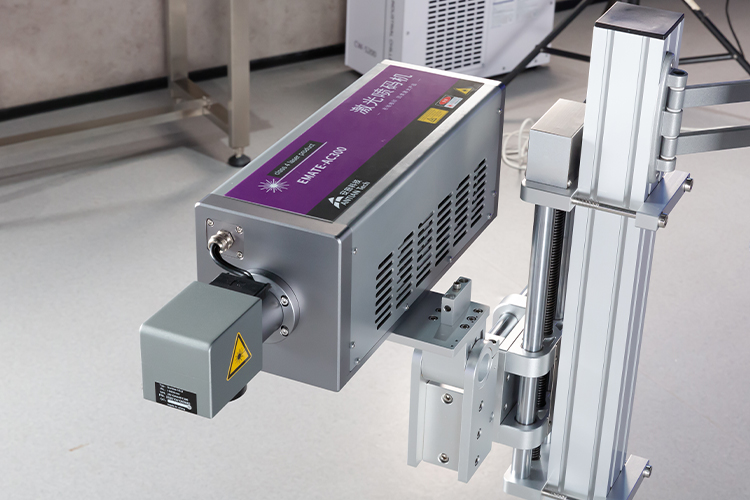

What is an Industrial UV Laser Marker?

A UV laser marking machine is a high-precision marking machine that usually uses an ultraviolet wavelength of 355 nm to mark surfaces with minimal heat. UV Laser Marking Technology enjoys the advantages of being able to do "cold marking" and, therefore, is very suitable for sensitive materials that may warp or burn under conventional fiber or CO₂ laser systems.

Core Features of Industrial UV Laser Markers

- Extremely fine beam for micro-marking

- High absorption rate on plastics, glass, ceramics, PCBs, and metals

- Minimal heat-affected zone

- Permanent, high-contrast markings

- Ability to engrave codes, serial numbers, barcodes, QR codes, and micro-text

Because of these advantages, UV laser markers are widely used in electronics manufacturing, medical device labeling, food and pharmaceutical packaging, and precision engineering industries.

Why UV Laser Technology Is Preferred in Modern Manufacturing

UV laser marking stands out because it can mark materials that other lasers cannot. Plastics with high transparency, glass that needs non-crack engraving, or delicate circuit boards requiring micro-etching—all benefit from UV laser precision.

Key Benefits:

- Non-contact and damage-free: The cold laser process ensures no deformation or burning.

- Extremely high clarity: Ideal for tiny components or dense marking fields.

- Long-lasting results: UV markings resist abrasion, chemicals, and heat.

- Eco-friendly: No inks, solvents, or consumables required.

But even the best technology depends on reliable manufacturing. This is where choosing the right Industrial UV Laser Marker supplier becomes essential.

Why Choosing a Trusted Industrial UV Laser Marker Supplier Matters

Selecting the correct supplier is more than just comparing prices. It directly impacts the performance of your marking system and the stability of your production line.

A reputable Industrial UV Laser Marker supplier uses high-end optical components, stable UV lasers, and durable galvanometer scanners. This ensures:

- Longer machine life

- More stable beam quality

- Higher marking speed

- Consistent precision

Cheaper factories often cut costs on optics, leading to poor marking quality and frequent breakdowns.

Key Factors to Evaluate in a UV Laser Marker Supplier

Technical Expertise and Certifications

Look for suppliers with:

- CE, FDA, ISO certifications

- Experienced R&D teams

- Proven industrial clients

These factors reflect strong engineering capability and reliability.

After-Sales Support and Training

A trustworthy supplier provides:

- Installation guidance

- Operator training

- Spare parts supply

- Quick-response service

UV laser systems require proper calibration, so support quality is crucial.

Customization and Integration Capability

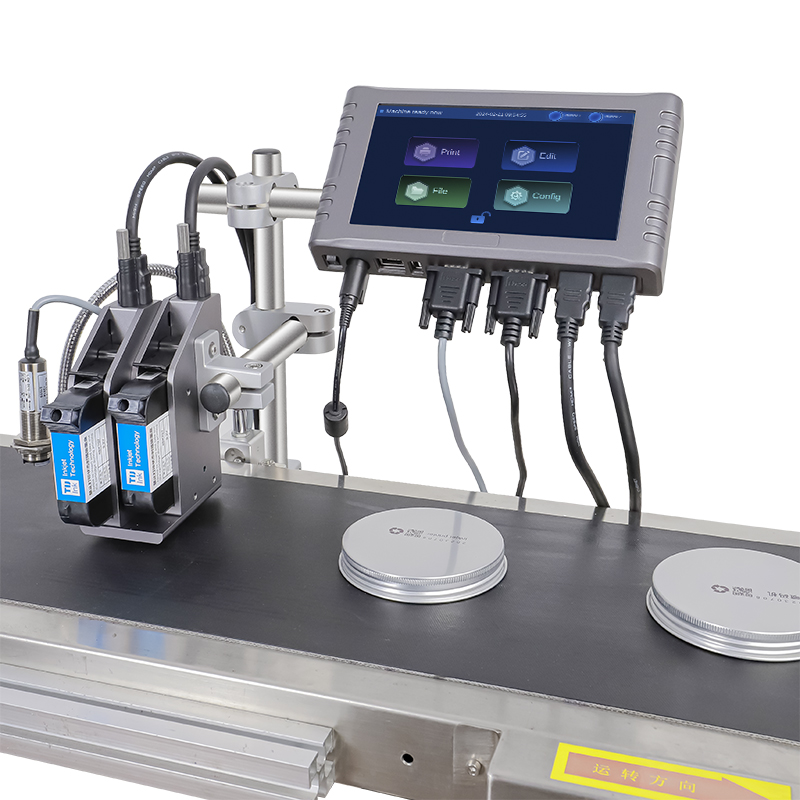

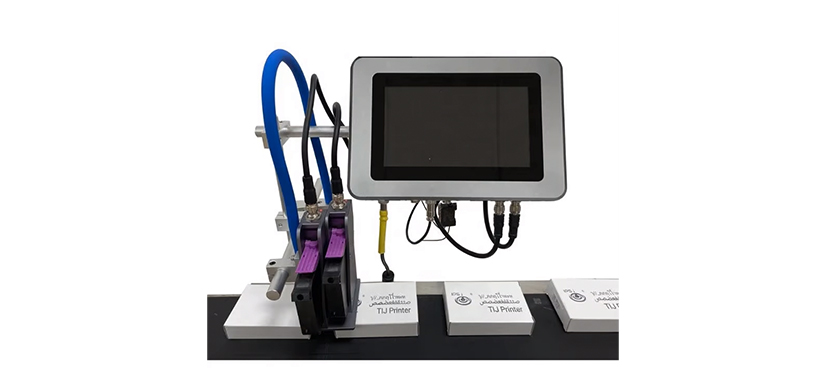

A good Industrial UV Laser Marker factory can integrate marking machines into:

- PLC-controlled systems

- Robotic arms

- Automated conveyor lines

This ensures seamless workflow compatibility.

Machine Stability and Warranty

Longer warranty periods and stable operation records show that the manufacturer uses durable components and stands behind their technology.

Conclusion: The Supplier You Choose Determines Your Production Quality

The full benefits of UV technology are only achieved when working with a reliable Industrial UV Laser Marker supplier or a technologically advanced Industrial UV Laser Marker factory.

Choosing the right manufacturer ensures:

- Stable marking performance

- Long-term durability

- Lower maintenance costs

- Efficient integration into your production line