TTO Printer – Enhancing Your Packaging Line with Precision Coding

Introduction: The Evolving Need for Efficient Coding in Packaging

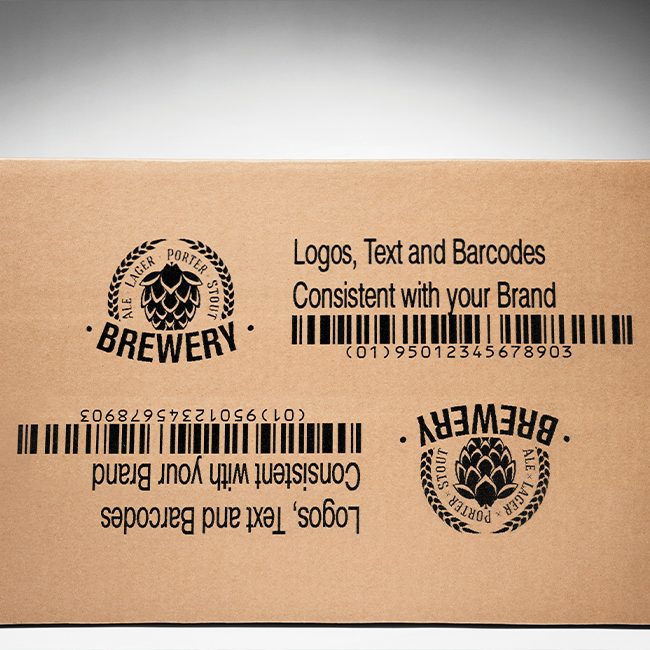

In modern manufacturing and packaging environments, precision, speed, and reliability in product coding are crucial for traceability and compliance. A TTO printer (Thermal Transfer Overprinter) offers a high-resolution, cost-effective solution for printing variable data such as barcodes, expiration dates, batch numbers, and QR codes directly onto flexible packaging films and labels. At Antian Coding, we specialize in advanced TTO printer solutions designed for seamless integration into various packaging lines, ensuring efficiency while maintaining crisp, permanent prints.

How TTO Printers Work

TTO printers use a thermal printhead combined with a ribbon to transfer ink onto packaging materials under heat and pressure. This method ensures sharp, high-resolution prints, even at high speeds, while maintaining low operational costs. Unlike traditional hot stamp or ink-based coding, TTO printers provide excellent clarity, reduce waste, and can handle a variety of materials, including flexible plastic films, foils, and labels, making them versatile for food, pharmaceutical, and cosmetic industries.

Benefits of Using TTO Printers

The use of TTO printers comes with significant benefits:

-

High-resolution printing (up to 300 dpi) ensures crisp barcodes and text.

-

Cost-effective coding with minimal ribbon waste.

-

Fast printing speeds without compromising print quality.

-

Clean, dry prints with no drying time required.

-

Capable of variable data printing in real-time for batch traceability.

Antian Coding’s TTO printers are engineered to handle demanding production environments while ensuring low maintenance and reduced operational downtime.

Why Choose Antian Coding for TTO Printers

Antian Coding’s TTO printers are designed with user-friendly interfaces and robust hardware, ensuring seamless integration into your packaging lines. With intelligent software, our printers allow easy adjustments for different packaging designs and coding needs, enabling operators to switch between production tasks efficiently. We offer comprehensive technical support and customization services, ensuring your TTO printer solution aligns precisely with your production requirements.

Applications Across Industries

TTO printers are widely used across industries requiring precise and durable coding, including:

-

Food Packaging: Printing expiration dates and batch codes on snack wrappers and pouches.

-

Pharmaceuticals: Printing lot numbers, expiry dates, and 2D barcodes on medical pouches.

-

Cosmetics: Batch and date coding on sachets and flexible film packs.

-

Electronics: Coding on protective films and labels for traceability.

By adopting TTO printers from Antian Coding, businesses can maintain compliance with regulatory standards while enhancing the quality and efficiency of their production lines.

FAQ: TTO Printer

Q1: What is a TTO printer used for?

TTO printers are used for high-resolution coding on flexible packaging, printing expiration dates, barcodes, and batch numbers.

Q2: What are the benefits of using a TTO printer over inkjet printers?

TTO printers provide dry, crisp prints without smudging, lower operational costs, and waste reduction, with high clarity suitable for barcodes and fine text.

Q3: Can Antian Coding customize TTO printers for specific packaging lines?

Yes, Antian Coding provides customization services to align TTO printers with specific production requirements and packaging materials.

Q4: What industries commonly use TTO printers?

Industries such as food packaging, pharmaceuticals, cosmetics, and electronics commonly use TTO printers for precise, durable coding.

Q5: Does Antian Coding provide technical support for TTO printers?

Yes, Antian Coding offers comprehensive technical support, ensuring seamless installation and ongoing maintenance.