Unlocking Precision: How CIJ Coders Are Revolutionizing Product Coding

CIJ coders bring unmatched speed and accuracy to product marking, transforming industries with reliable, high-resolution, and non-stop coding solutions.

Introduction to CIJ Coding Technology

Continuous Inkjet (CIJ) coding has emerged as a critical solution in modern manufacturing and packaging lines, providing fast, non-contact, and highly reliable printing capabilities. Whether you’re producing beverage bottles, food containers, pharmaceuticals, or automotive parts, CIJ coders deliver consistent code quality without interrupting the production flow. Unlike thermal or laser printing technologies, CIJ systems excel on curved, rough, or porous surfaces, making them a go-to choice for many industries.

What Is a CIJ Coder?

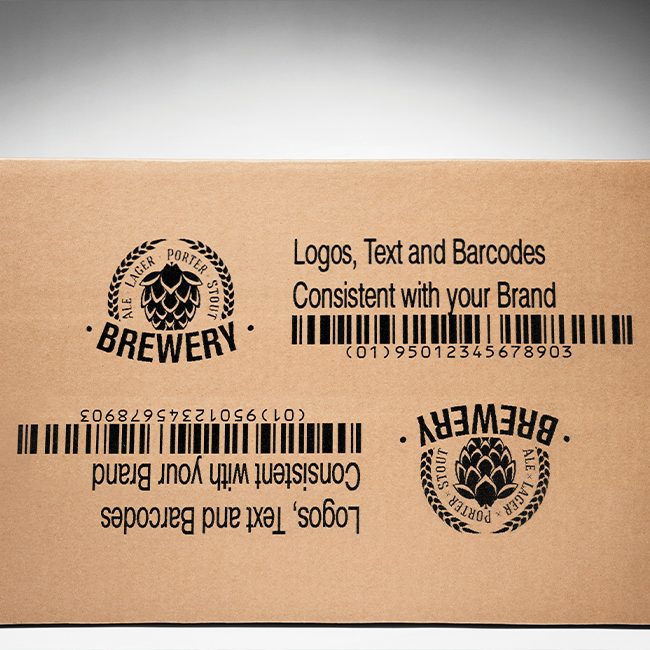

A CIJ coder is a printing machine designed to mark products with date codes, batch numbers, barcodes, logos, or regulatory information using a stream of ink droplets. The ink is expelled through a high-pressure nozzle and electrically charged to control its trajectory onto the substrate. This allows for extremely fine and fast marking—even on fast-moving production lines exceeding 300 meters per minute.

· CIJ coders are particularly suited for industries where speed and clarity of printed codes are essential for traceability and compliance.

Advantages of CIJ Coding in Industrial Applications

The adoption of CIJ coding is widespread due to its flexibility, high-speed capabilities, and low maintenance needs. A major advantage is its ability to function on virtually any material: plastic, glass, metal, cardboard, and even flexible packaging. CIJ coders offer minimal downtime thanks to self-cleaning printheads and continuous ink circulation systems. In sectors like food and beverage, the ability to print legible expiry dates and batch numbers on wet or uneven surfaces is indispensable. Moreover, the small character size ensures codes don’t obscure branding or regulatory labels.

Application Scenarios: Where CIJ Coders Excel

CIJ coding technology finds its place across a diverse range of sectors. In the electronics industry, coders are used to apply serial numbers and QR codes on components as small as a fingernail. In pharmaceuticals, CIJ printers provide batch and manufacturing data critical to patient safety. Packaging lines for soft drinks rely heavily on the quick-dry and smudge-resistant properties of CIJ inks to maintain clarity. Even in construction materials like PVC pipes and cables, CIJ printers ensure traceability without compromising on durability.

Ink Formulations and Environmental Considerations

Modern CIJ coders are compatible with a wide range of inks tailored to meet application-specific demands. From fast-drying alcohol-based inks for high-speed packaging to pigmented inks for dark surfaces, the range is extensive. Many manufacturers now focus on low-VOC and MEK-free options to reduce environmental impact. Newer CIJ coding systems also incorporate energy-saving features and automatic standby modes to support sustainable manufacturing practices.

CIJ Coders vs. Other Printing Technologies

Compared to thermal inkjet (TIJ) and laser coding, CIJ offers a balance between cost, versatility, and performance. While TIJ is known for high-resolution printing, it often falls short in high-speed environments or non-porous surfaces. Laser coders, on the other hand, require substantial investment and are limited in material compatibility. CIJ strikes the ideal middle ground, offering scalable solutions for small manufacturers and global corporations alike.

Choosing the Right CIJ Coder for Your Business

Selecting the best CIJ coder depends on multiple factors: print speed, substrate compatibility, environmental conditions, and ink type. Businesses must also consider integration with existing production lines, regulatory needs, and future scalability. Brands like RHI Electric (as found on rhielectric.com) offer a wide array of CIJ coding solutions tailored to meet the rigorous demands of high-volume, precision-oriented production.

Future Trends in CIJ Coding

The future of CIJ coding lies in smart connectivity, IoT integration, and even AI-powered predictive maintenance. Modern CIJ coders are increasingly equipped with touchscreen interfaces, real-time monitoring dashboards, and cloud-based data reporting, allowing operators to maximize uptime and reduce operational errors. As industries continue to digitalize, the demand for seamless, automated, and intelligent coding solutions will only grow.

FAQ

Q1: What materials can a CIJ coder print on?

A1: CIJ coders can print on a variety of materials including metal, glass, plastic, paper, and flexible films.

Q2: How fast can CIJ coders print?

A2: Depending on the model, CIJ coders can print at speeds exceeding 300 meters per minute, ideal for high-speed production lines.

Q3: Is CIJ coding environmentally friendly?

A3: Many CIJ systems support MEK-free inks and energy-saving features, making them more sustainable than traditional options.