Laser Marking Machine – Precision, Efficiency, and Versatility for Modern Industries

Introduction: Why Laser Marking Machines Are Essential Today

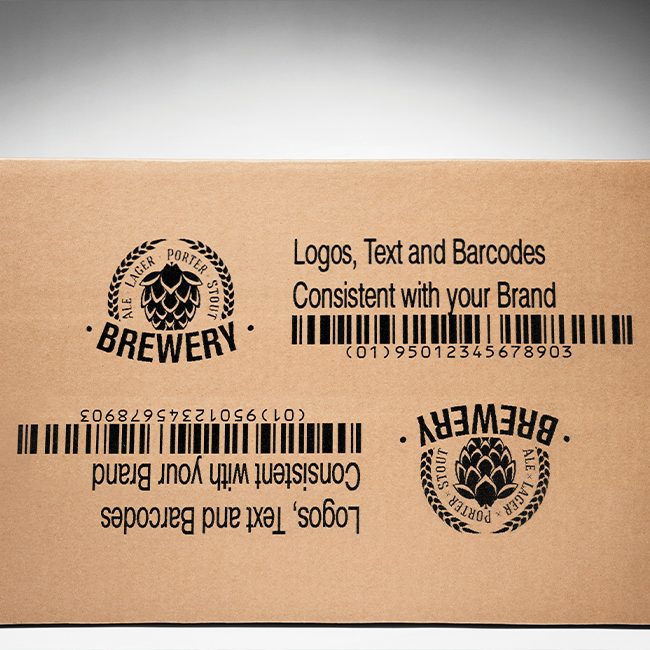

In today’s fast-paced manufacturing environments, the laser marking machine has become a critical tool for industries requiring permanent, precise, and high-speed marking on a wide range of materials. Whether marking barcodes, QR codes, logos, or serial numbers, laser marking machines deliver non-contact, environmentally friendly, and maintenance-light solutions. At Antian Coding, we specialize in manufacturing high-performance laser marking machines that cater to diverse sectors including automotive, electronics, medical devices, and packaging industries.

What is a Laser Marking Machine?

A laser marking machine utilizes a focused laser beam to create permanent marks on the surface of materials. This technology works by altering the surface properties of materials through localized heating, carbonization, foaming, or ablation, depending on the type of laser and material. Unlike traditional printing, laser marking ensures durability and legibility even under harsh environmental conditions.

Benefits of Using Laser Marking Machines

Laser marking machines offer several advantages:

-

Precision and Clarity: They produce high-resolution marks that are easy to read and scan.

-

Speed and Efficiency: Suitable for high-volume production lines while maintaining accuracy.

-

Non-contact Process: Minimizes wear and tear, reducing maintenance and consumable costs.

-

Versatility: Can mark on metals, plastics, ceramics, glass, and more.

-

Eco-Friendly: No ink or chemical waste, supporting sustainable manufacturing processes.

Types of Laser Marking Machines at Antian Coding

Antian Coding offers a range of laser marking machines:

-

Fiber Laser Marking Machines: Ideal for marking metals and some plastics with deep engraving capabilities.

-

CO2 Laser Marking Machines: Suitable for non-metallic materials like wood, glass, and plastics.

-

UV Laser Marking Machines: Perfect for high-precision applications requiring minimal thermal impact on materials, such as in the electronics and medical industries.

Each machine is designed to offer maximum marking quality while ensuring easy integration into existing production lines.

Applications Across Industries

Laser marking machines from Antian Coding are used for:

-

Engraving serial numbers on automotive parts for traceability.

-

Marking QR codes and barcodes on electronic components.

-

Branding and customization of consumer products.

-

Producing medical device markings compliant with regulatory requirements.

By utilizing our laser marking machines, businesses can enhance product traceability, ensure regulatory compliance, and add value through customized branding.

Why Choose Antian Coding’s Laser Marking Machines

Antian Coding prioritizes technological innovation and quality, ensuring our laser marking machines meet high industry standards. We offer machines with user-friendly interfaces, robust designs for industrial environments, and support seamless integration with automated production lines. Our global service network ensures timely support, helping clients maintain consistent operations.

FAQ: Laser Marking Machine

Q1: What materials can a laser marking machine mark on?

Metals, plastics, glass, ceramics, leather, and more.

Q2: Is laser marking environmentally friendly?

Yes, it produces no ink waste or chemical emissions.

Q3: What industries benefit from laser marking machines?

Automotive, electronics, medical, packaging, and consumer goods industries.

Q4: What are the differences between fiber, CO2, and UV laser marking machines?

Fiber lasers are best for metals, CO2 lasers for non-metals, and UV lasers for high-precision, low-heat applications.

Q5: Does Antian Coding provide after-sales support for laser marking machines?

Yes, we offer global technical support and training for our customers.