Antian Coding Equipment — Print on a Wide Range of Materials with Ease

When your production line handles multiple product types — from rigid cartons to plastic bottles, metal parts to flexible films — choosing a coding solution that adapts seamlessly can make all the difference. Antian coding equipment is engineered to deliver crisp, reliable printing across a wide range of materials, helping manufacturers avoid costly rework and inconsistent marking.

In many factories, a coding system isn’t an afterthought — it’s a core part of traceability, compliance, and brand image. Let’s look at how Antian empowers businesses with versatile, industrial-grade printing solutions.

Why Material Compatibility Matters

Different substrates interact with ink in different ways. For example:

-

Paperboard absorbs ink quickly but may cause bleeding

-

Plastic surfaces often need fast-drying, high-adhesion ink

-

Metal and glass are smooth and non-porous, requiring specialized formulas

-

Flexible films can stretch or move during printing

A system that isn’t tuned for your material can lead to blurry marks, ink smudges, poor barcode readability, and overall lower production line efficiency.

Antian understands these challenges — and designs coding solutions accordingly.

Material Compatibility Chart — Antian Coding Equipment

| Material Type | Recommended Antian Solution | Typical Applications |

|---|---|---|

| Carton & Paperboard | TIJ / Handheld | Packaging, logistics codes |

| Plastic (Rigid & Film) | TIJ & Handheld with Adhesive Ink | Bottles, pouches |

| Metal | Handheld with High-Adhesion Ink | Pipes, sheets, parts |

| Wood | Handheld | Furniture, lumber |

| Glass | Handheld with Special Ink | Bottles, containers |

| Flexible Film | TIJ Printing | Bags, wraps |

| Coated Surfaces | High-Adhesion Ink Options | Labels, glossy materials |

This table highlights how Antian matches equipment and ink formulations to specific material characteristics — ensuring stable, readable codes every time.

Antian Coding Equipment in Real Applications

📦 Cartons & Paper Packaging

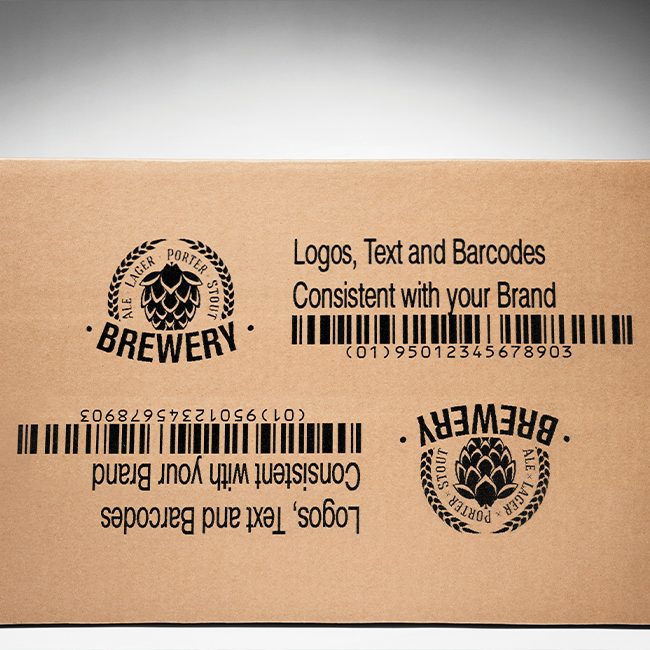

In logistics and retail packaging, printing batch numbers, barcodes, and expiry dates is a daily necessity. Antian’s thermal inkjet and handheld printers deliver:

-

Sharp text and machine-readable codes

-

Fast drying that prevents smudging

-

Stable operation even on high-speed packing lines

For many warehouses, a combination of fixed and handheld systems gives the best balance of automation and flexibility.

🛢️ Plastic Products — Rigid & Flexible

Plastic surfaces can be tricky because they’re non-porous — ink sits on top instead of absorbing. Antian’s specially formulated plastic inks ensure:

-

Strong adhesion

-

Minimal run-off

-

Resistance to heat and humidity

Whether it’s PET bottles or shrink films, print clarity stays consistent.

⚙️ Metal & Construction Materials

Metal sheets, pipes, and parts demand both durability and readability. Antian handheld printers with high-adhesion ink allow operators to apply:

-

Serial numbers

-

Production dates

-

Batch codes

directly onto metal surfaces without costly pre-treatment.

Wood & Glass

Materials like wood and glass have very different surface properties — one porous and rough, the other smooth and reflective. Antian coding solutions adapt by offering:

-

Ink types that penetrate textured surfaces

-

Ink formulas that bond on smooth glass without smearing

This versatility reduces the need to buy multiple machines or outsourcing printing altogether.

How Antian Ensures Reliable Printing on Diverse Substrates

Antian’s success in material compatibility comes from focusing on:

1. Optimized Ink Formulations

Industrial-grade inks designed for adhesion, durability, and fast drying — even on non-porous substrates.

2. Adjustable Print Parameters

Operators can fine-tune:

-

Print speed

-

Dot density

-

Temperature settings (where applicable)

to match material behavior.

3. Flexible Equipment Options

From handheld printers to thermal inkjet systems, Antian provides:

-

Portable flexibility for irregular or large items

-

Fixed systems for high-speed automated lines

This ensures you choose the right tool for the job — not a one-size-fits-all compromise.

Practical Tips for Choosing the Right Printer

Before selecting a coding machine, consider:

-

What materials will you print on most often?

-

Do you need mobility or line integration?

-

What is your expected daily printing volume?

-

Do you require variable data printing?

A solution that fits your current needs — and anticipates future changes — adds the most value.

Work with a Coding Partner That Understands Your Materials

Antian doesn’t just sell machines — we help you implement solutions that work across the materials you use. Our team provides:

-

Material compatibility consultation

-

Sample testing with your own substrates

-

Customized ink solutions

-

OEM/ODM configurations

This depth of support is especially valuable for manufacturers handling mixed product lines, seasonal packaging changes, or multi-surface logistics operations.

Get Your Customized Material Compatibility Plan

Whether you’re printing on cartons, plastics, metal, wood, glass, or flexible films, Antian has a solution that fits.

📌 Tell us:

-

Your primary substrate types

-

Print size and content

-

Production speed requirements

We will recommend the best equipment and ink combination — and provide a competitive quote.

👉 Contact Antian now for a tailored solution and quotation!