Thermal Inkjet Printer for Modern Industrial Coding

In manufacturing, details matter. A blurred expiration date or unreadable barcode can lead to compliance risks, returned products, or brand damage. That’s why more factories are turning to the Thermal Inkjet Printer (TIJ printer) — a compact yet powerful solution designed for clean, high-resolution coding on modern production lines.

At Antian, we don’t just supply printers. We help businesses build reliable traceability systems that work day after day.

What Makes a Thermal Inkjet Printer Different?

Unlike traditional ink systems that rely on complex ink circulation, a thermal inkjet printer works with cartridge-based thermal bubble technology. The structure is simpler, cleaner, and easier to manage.

In practical terms, that means:

-

No complicated ink pipelines

-

No frequent cleaning procedures

-

No messy refilling process

-

Faster cartridge replacement

For many production managers, this simplicity is the biggest advantage. Less maintenance means less downtime — and less downtime means more output.

Why More Factories Are Switching to TIJ Technology

Production environments are getting faster and more automated. Coding systems must keep up.

A thermal inkjet printer offers:

-

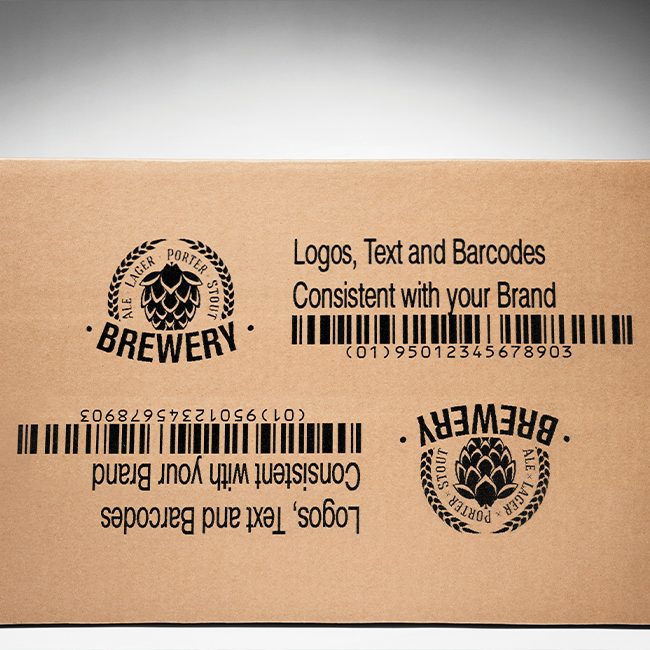

High resolution up to 600 DPI

-

Sharp QR codes and barcodes

-

Clear small fonts for pharmaceutical and cosmetic labels

-

Stable performance on high-speed lines

But beyond the specs, there’s a practical reason companies prefer TIJ: it simply works without constant supervision. Operators don’t need specialized technical training, and adjustments are straightforward.

Thermal Inkjet vs Traditional CIJ: A Quick Comparison

To better understand where TIJ stands, here is a simple comparison:

| Feature | Thermal Inkjet Printer (TIJ) | Continuous Inkjet (CIJ) |

|---|---|---|

| Print Resolution | Up to 600 DPI (high clarity) | Lower resolution |

| Maintenance | Low, cartridge-based | High, complex ink system |

| Operation | Simple & clean | Requires technical setup |

| Ideal For | High-resolution coding | High-speed simple coding |

| Installation | Compact & flexible | Larger system footprint |

If your priority is crisp printing and easier maintenance, TIJ is often the smarter investment.

Designed for Real Production Environments

A thermal inkjet printer isn’t just about printing text. It’s about adapting to real factory conditions.

It can be integrated into:

-

Carton sealing machines

-

Labeling systems

-

Filling and packaging lines

-

Conveyor-based automatic production

Whether printing on cartons, plastic bottles, aluminum foil bags, or coated surfaces, the right ink choice ensures fast drying and strong adhesion.

In industries like food and pharmaceuticals, where compliance and traceability are critical, consistent print quality becomes a daily necessity — not an option.

Key Features of Antian Thermal Inkjet Printers

At Antian, our systems are designed with industrial practicality in mind:

-

User-friendly touchscreen interface

-

Variable data printing capability

-

Multi-language system support

-

Flexible print height configuration

-

USB and data communication integration

-

Stable performance for continuous operation

We understand that every production line has its own rhythm. That’s why we offer customizable configurations to match different speeds, materials, and installation spaces.

Typical Application Scenarios

Some of the most common uses include:

-

Food & Beverage: production dates, batch numbers, QR traceability codes

-

Pharmaceutical: expiration dates, lot numbers, regulatory data

-

Electronics: serial numbers and tracking codes

-

E-commerce logistics: barcode printing on shipping cartons

If your products need identification, traceability, or branding information, a thermal inkjet printer is likely the most efficient solution.

Choosing the Right Thermal Inkjet Printer

Before selecting a model, consider:

-

What material are you printing on?

-

What print height do you require?

-

How fast is your production line?

-

Do you need variable data or database connectivity?

A good coding system should match your workflow — not force you to adjust your workflow around it.

Work with a Reliable Thermal Inkjet Printer Manufacturer

At Antian, we focus on more than just equipment sales. We support clients with:

-

Technical consultation

-

Sample testing

-

OEM/ODM customization

-

Competitive factory pricing

-

Responsive after-sales service

If you’re planning to upgrade your coding system or integrate a new production line, our team can help you find the right configuration quickly and efficiently.

Request a Quote Today

A high-quality Thermal Inkjet Printer can improve your production efficiency, enhance brand credibility, and reduce long-term maintenance costs.

Tell us your application requirements — material type, production speed, and print size — and we will recommend the most suitable solution.